Innovation Activities

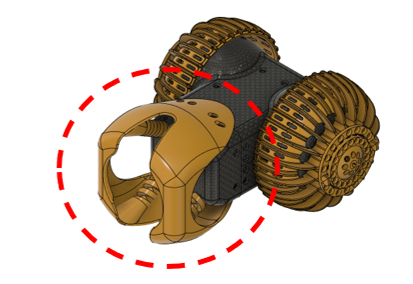

Components with Compliant Mechanism Design Adopted for Lunar Rover YAOKI

Resin components with compliant mechanism design—integrating our material expertise and advanced technologies in structural design and optimization simulation—have been adopted for the lunar rover YAOKI, developed by Dymon Co., Ltd. In March 2025, YAOKI successfully captured images of the lunar surface and transmitted the data back to Earth—a milestone achieved for the first time by a private-sector project in Japan.

Related article:

Apr. 12, 2024 Components with Compliant Mechanism Design Adopted for Lunar Rover YAOKI

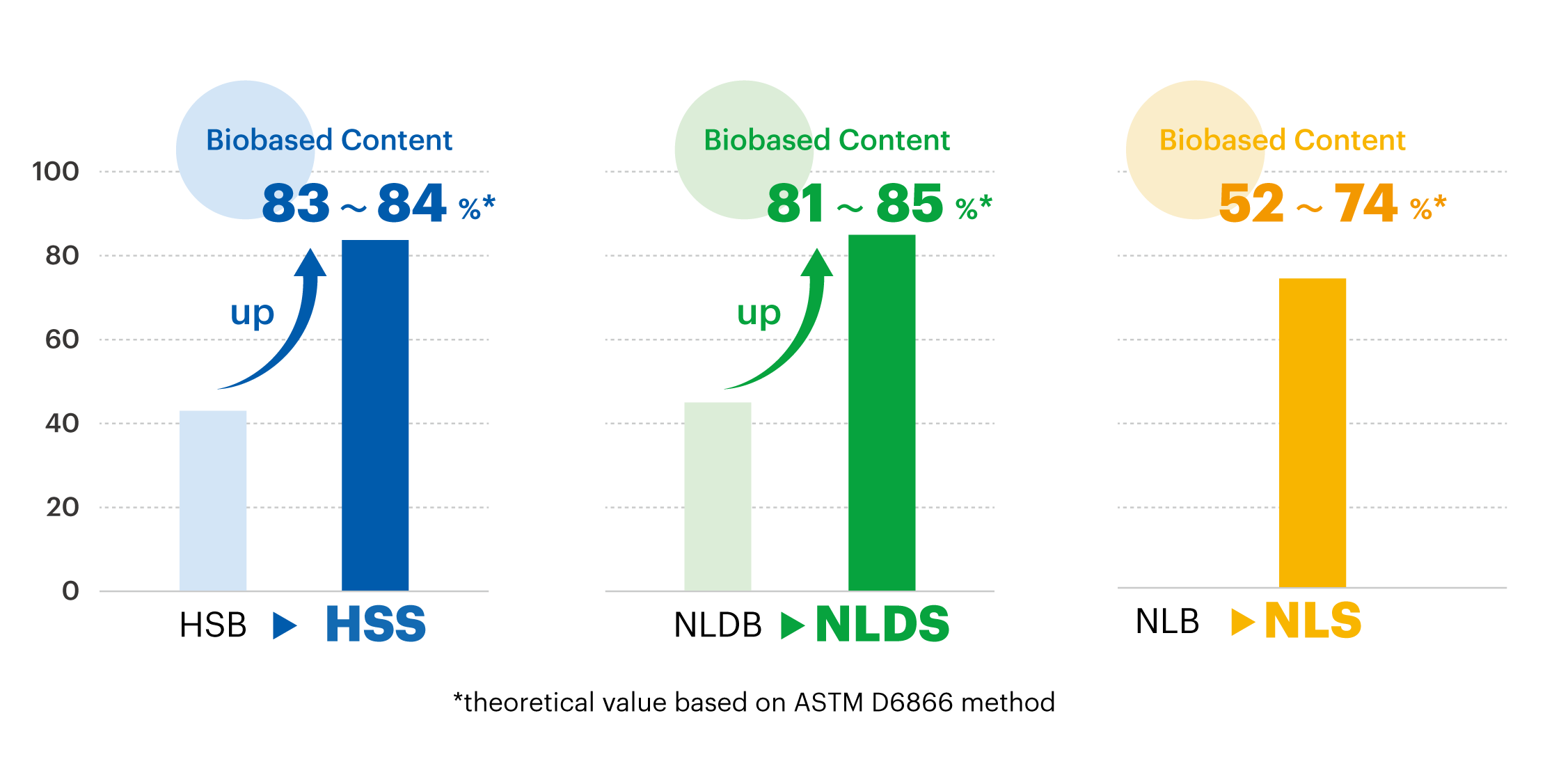

BENEBiOL™—Introducing New Grades with Higher Biomass Content

In October 2024, we launched new grades of BENEBiOL™, a biomass-based polycarbonatediol. These grades offer higher biomass content while ensuring excellent properties, including flexibility without compromising chemical resistance, stain resistance, and a distinctive tactile feel.

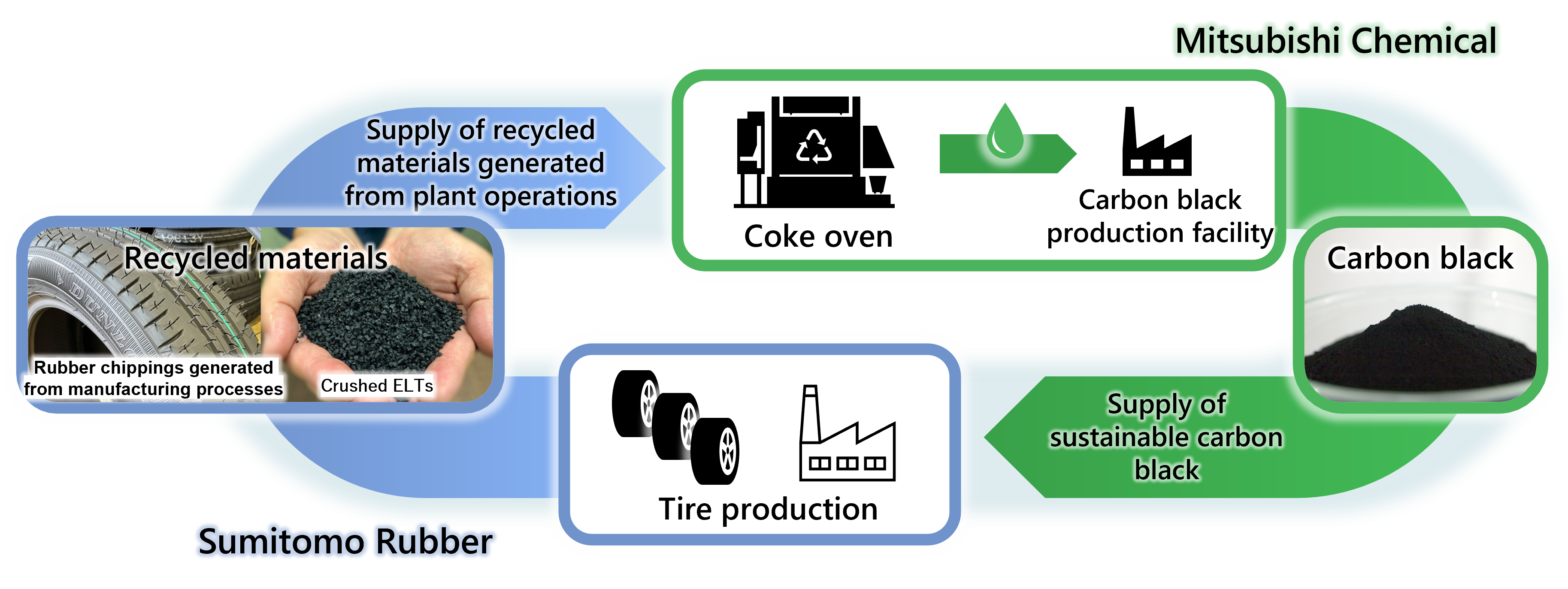

Studies on Chemical Recycling of End-of-Life Tires Using Coke Ovens

In July 2024, we began studying the chemical recycling of end-of-life tires using coke ovens at our Kagawa Plant, aiming to launch sustainable carbon black in fiscal 2025. This marks the world’s first initiative to commercialize sustainable carbon black recycled from end-of-life tires using coke ovens.

Related article:

Joint Carbon Black Recycling Project for Tires Launched with Sumitomo Rubber

In January 2025, we launched a joint chemical recycling project with Sumitomo Rubber Industries, Ltd. as part of our commitment to resource circulation. Through this project, carbon black, a key material used in tires, is recovered from rubber chippings generated during tire manufacturing and from crushed end-of-life tires, and then reused in tire production.

Related article:

Comprehensive Partnership Agreement to Promote Recycling of Plastic Packaging

In February 2025, we entered into a comprehensive partnership agreement with Kashima City (Ibaraki Prefecture), REFINVERSE, Inc., Toyo Seikan Group Holdings, Ltd., Kewpie Corporation, and KASUMI CO., LTD. to promote closed-loop recycling of plastic packaging in Ibaraki Prefecture. A pilot project to recycle collected used plastics at a chemical recycling plant is scheduled to begin in 2025.

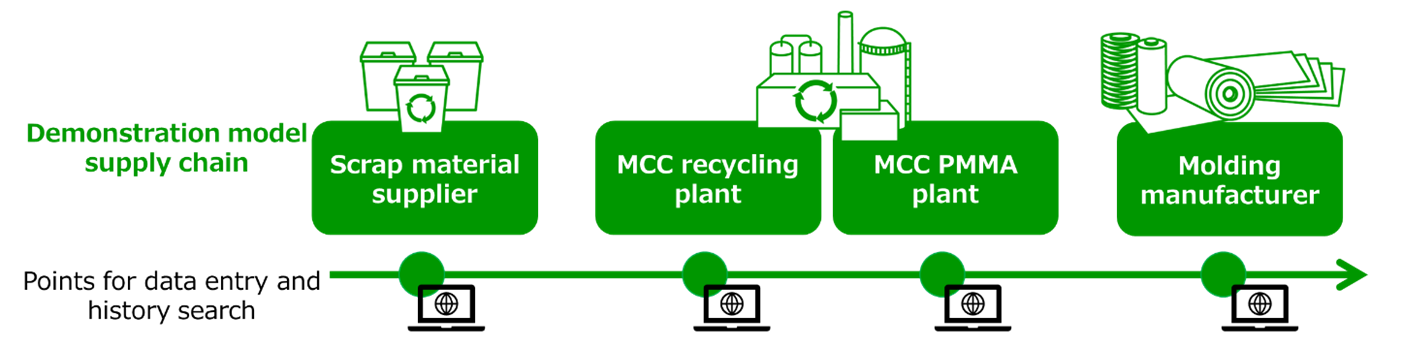

Demonstration Tests with Chaintope on Traceability System for Chemical Recycling

We conducted demonstration tests on a traceability system in collaboration with Chaintope Inc. The system is designed to help establish transparent and reliable supply chains by enabling tamper-proof management and sharing of information such as the types of waste plastics used as feedstock for recycling.