The Mitsubishi Chemical Group’s Highly Rigid and Lightweight Aerospace Materials Contribute to Image Capture and Image Data Transmission by the Lunar Rover YAOKI

March 17, 2025

The lunar rover YAOKI, made from aerospace materials provided by the Mitsubishi Chemical Group (“MCG Group”) reached the moon before dawn on March 7, 2025, Japan time, and succeeded in capturing images of the lunar surface and sending the image data to Earth. YAOKI was developed by Dymon Co., Ltd., a venture company specializing in robotics and space development. Under the private sector project in which this startup as well as the MCG Group participated, YAOKI became Japan’s first private sector lunar rover to operate on the moon.

Image captured by YAOKI, The bright part on the upper left is a part of a lunar crater

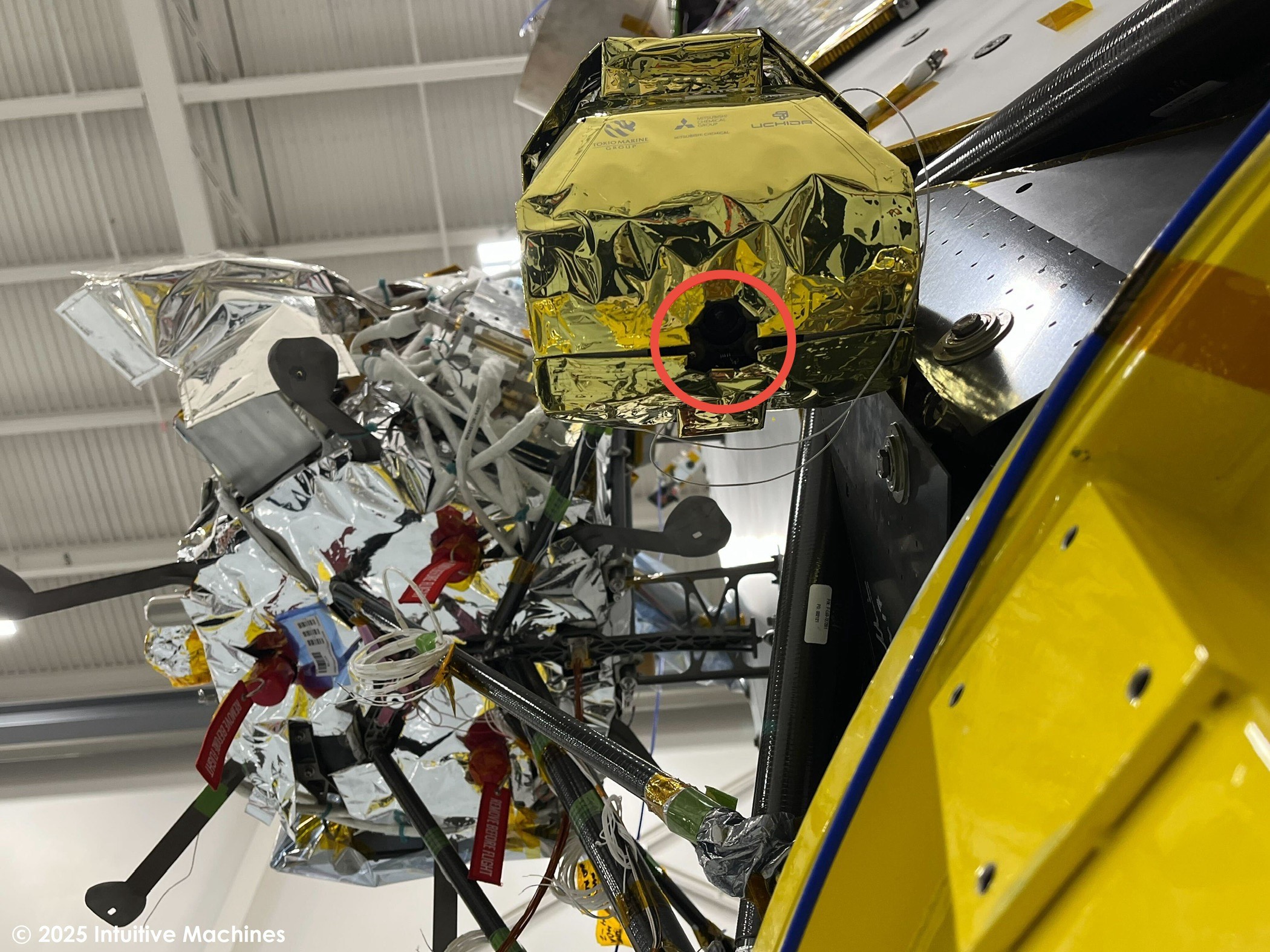

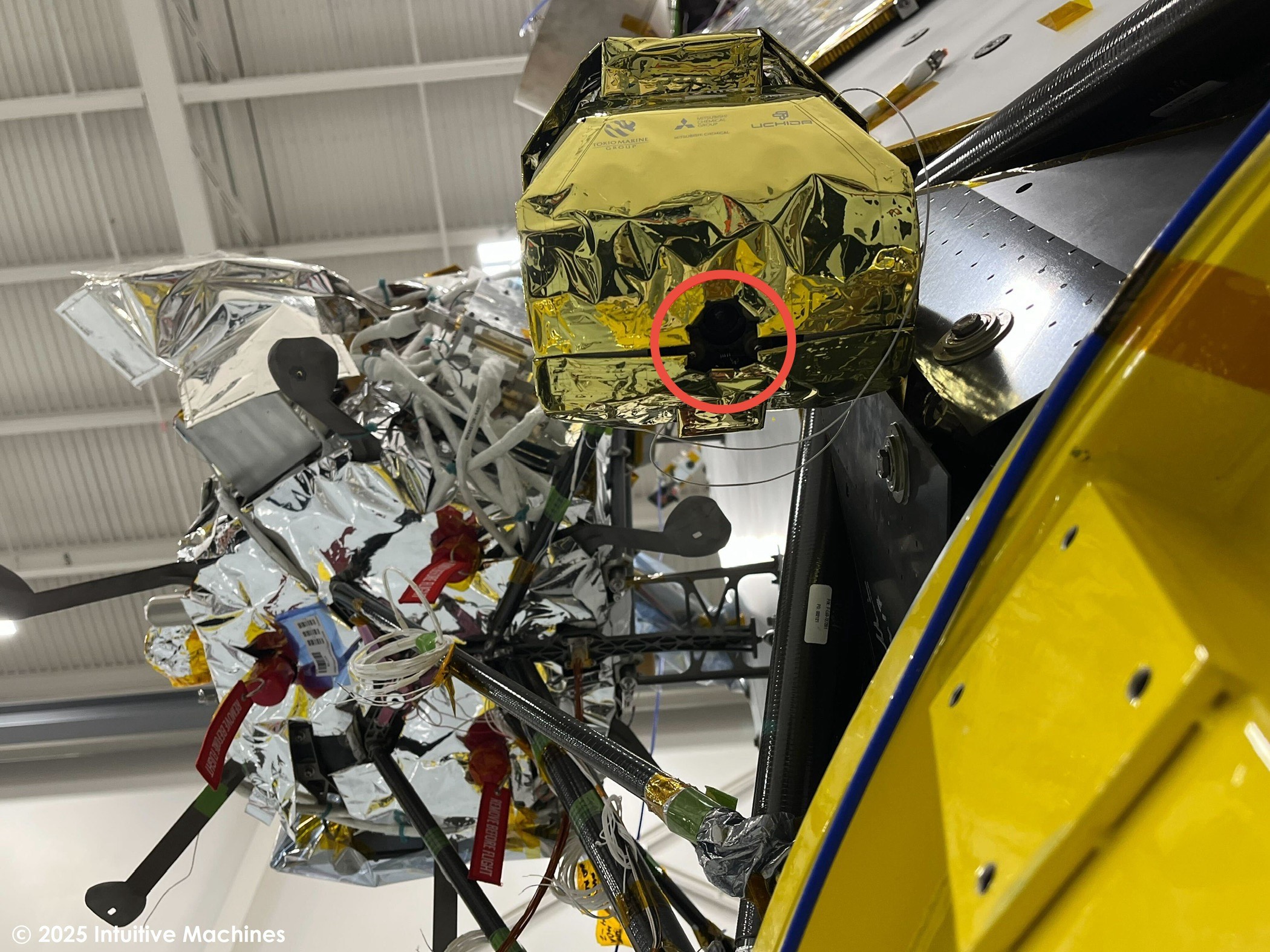

YAOKI’s camera position, from which photos were taken

The lunar lander of the U.S. space developer Intuitive Machines, on which YAOKI was riding, toppled over on to its side when landing the moon. Due to this, YAOKI could not be released from the lander to run on the moon’s surface as initially planned. However, YAOKI, aboard the lunar lander, captured images of the moon and sent the data to Earth. Also, thanks to the data obtained about YAOKI from launch to the end of the mission, it has been confirmed on Earth that all its intended functions work appropriately on the moon, including the rotation of the wheels.

(Reference) Press release on lunar rover YAOKI, which became the first Japanese private sector lunar rover to reach the moon and capture its images (by Dymon, dated March 8, 2025) (in Japanese only)

https://dymon.co.jp/news/yaoki_on_the_moon_20250307/

Due to participation in the space-related market by companies from the private sector, the market has been expanding globally, and the market size is predicted to reach 140 trillion yen by 2040.* In and after fiscal 2025, the MCG Group, driven by the YAOKI-related project, will launch new aerospace projects, including a project to develop new materials for lunar exploration and a project to develop an innovative graphite sheet business. Through these projects, the MCG Group aims to create innovative solutions by combining a range of highly competitive technologies.

* Refer to material 5 prepared for the first meeting of the Subcommittee on Space Industry under the Manufacturing Industry Committee of the Industrial Structure Council (Ministry of Economy, Trade and Industry, March 25, 2024) (in Japanese only)

https://www.meti.go.jp/shingikai/sankoshin/seizo_sangyo/space_industry/001.html

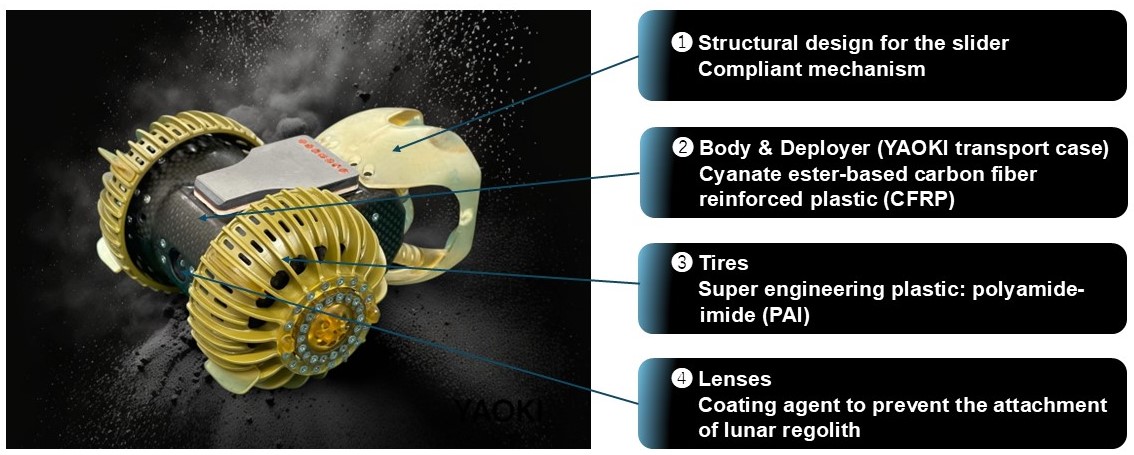

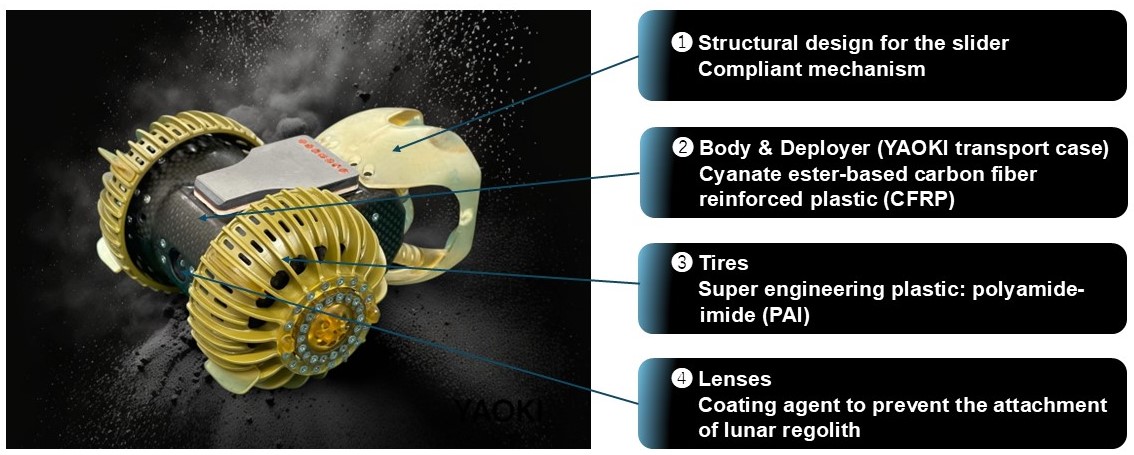

■The MCG Group’s products and technologies used in YAOKI

For YAOKI, highly rigid and lightweight aerospace materials created by “connecting the MCG Group’s technologies” are adopted, as outlined in the following four items. Combining its proprietary technologies, the Group has contributed to both weight reduction and greater shock resistance of the lunar rover.

1. Structural design for the slider: Compliant mechanism

Through one-piece injection molding using super engineering plastics, a complex shape that is impossible to form by ordinary injection molding has been realized for the lunar rover.

Press release dated April 12, 2024: “Components with Compliant Mechanism Design Adopted for Lunar Rover YAOKI”

https://www.mcgc.com/english/news_release/01926.html

2. Body & Deployer (YAOKI transport case): Cyanate ester-based carbon fiber reinforced plastic (CFRP)

The cyanate ester-based carbon fiber reinforced plastic provides both high thermal resistance and strength. By replacing the conventional aluminum material with CFRP, the lunar rover’s safety factor has been increased five-fold for shock resistance, along with enhanced resistance against the harsh temperature environment on the moon. Moreover, the weight of the rover was reduced by 30%.

3. Tires: Super engineering plastic: polyamide-imide (PAI)

The tires are made from a super engineering plastic called polyamide-imide (PAI) by extrusion/compression molding and can be continuously used at a temperature as high as 250℃. Due to the use of this material, the tires are highly cold-, heat-, abrasion- and shock-resistant and can endure shocks caused by a fall.

4. Lenses: Coating agent to prevent the attachment of lunar regolith

This coating agent helps prevent lunar regolith, which covers the moon, from being attached to the lenses. Lunar regolith is made of sharp-pointed particles, each of which is about 50 microns (1/20 of 1 mm) in size. The coating agent prevents these particles blown into the air when the lunar rover is running on the moon surface from being attached to the lenses.

Exhibited at 2025 International Space Industry Exhibition (p.18)

https://www.m-chemical.co.jp/en/products/departments/mcc/cfcm/expo/2025ISIEX_en.pdf

Image captured by YAOKI, The bright part on the upper left is a part of a lunar crater

YAOKI’s camera position, from which photos were taken

The lunar lander of the U.S. space developer Intuitive Machines, on which YAOKI was riding, toppled over on to its side when landing the moon. Due to this, YAOKI could not be released from the lander to run on the moon’s surface as initially planned. However, YAOKI, aboard the lunar lander, captured images of the moon and sent the data to Earth. Also, thanks to the data obtained about YAOKI from launch to the end of the mission, it has been confirmed on Earth that all its intended functions work appropriately on the moon, including the rotation of the wheels.

(Reference) Press release on lunar rover YAOKI, which became the first Japanese private sector lunar rover to reach the moon and capture its images (by Dymon, dated March 8, 2025) (in Japanese only)

https://dymon.co.jp/news/yaoki_on_the_moon_20250307/

Due to participation in the space-related market by companies from the private sector, the market has been expanding globally, and the market size is predicted to reach 140 trillion yen by 2040.* In and after fiscal 2025, the MCG Group, driven by the YAOKI-related project, will launch new aerospace projects, including a project to develop new materials for lunar exploration and a project to develop an innovative graphite sheet business. Through these projects, the MCG Group aims to create innovative solutions by combining a range of highly competitive technologies.

* Refer to material 5 prepared for the first meeting of the Subcommittee on Space Industry under the Manufacturing Industry Committee of the Industrial Structure Council (Ministry of Economy, Trade and Industry, March 25, 2024) (in Japanese only)

https://www.meti.go.jp/shingikai/sankoshin/seizo_sangyo/space_industry/001.html

■The MCG Group’s products and technologies used in YAOKI

For YAOKI, highly rigid and lightweight aerospace materials created by “connecting the MCG Group’s technologies” are adopted, as outlined in the following four items. Combining its proprietary technologies, the Group has contributed to both weight reduction and greater shock resistance of the lunar rover.

1. Structural design for the slider: Compliant mechanism

Through one-piece injection molding using super engineering plastics, a complex shape that is impossible to form by ordinary injection molding has been realized for the lunar rover.

Press release dated April 12, 2024: “Components with Compliant Mechanism Design Adopted for Lunar Rover YAOKI”

https://www.mcgc.com/english/news_release/01926.html

2. Body & Deployer (YAOKI transport case): Cyanate ester-based carbon fiber reinforced plastic (CFRP)

The cyanate ester-based carbon fiber reinforced plastic provides both high thermal resistance and strength. By replacing the conventional aluminum material with CFRP, the lunar rover’s safety factor has been increased five-fold for shock resistance, along with enhanced resistance against the harsh temperature environment on the moon. Moreover, the weight of the rover was reduced by 30%.

3. Tires: Super engineering plastic: polyamide-imide (PAI)

The tires are made from a super engineering plastic called polyamide-imide (PAI) by extrusion/compression molding and can be continuously used at a temperature as high as 250℃. Due to the use of this material, the tires are highly cold-, heat-, abrasion- and shock-resistant and can endure shocks caused by a fall.

4. Lenses: Coating agent to prevent the attachment of lunar regolith

This coating agent helps prevent lunar regolith, which covers the moon, from being attached to the lenses. Lunar regolith is made of sharp-pointed particles, each of which is about 50 microns (1/20 of 1 mm) in size. The coating agent prevents these particles blown into the air when the lunar rover is running on the moon surface from being attached to the lenses.

Exhibited at 2025 International Space Industry Exhibition (p.18)

https://www.m-chemical.co.jp/en/products/departments/mcc/cfcm/expo/2025ISIEX_en.pdf