Conducting Demonstration Tests of a Traceability System for Chemical Recycling in Collaboration with Chaintope Inc. to Build Transparent and Reliable Supply Chains

October 28, 2024

Since FY2023, MCC has participated in the "Establishing Environmental Testing, Diagnostics, and Tracer Technologies and Building a Digital Analysis Platform for Industrial Applications" project led by the National Institute for Materials Science (NIMS) under the Cabinet Office's 3rd period of the Cross-ministerial Strategic Innovation Promotion Program (SIP) based on the theme of "Building a Circular Economy System."

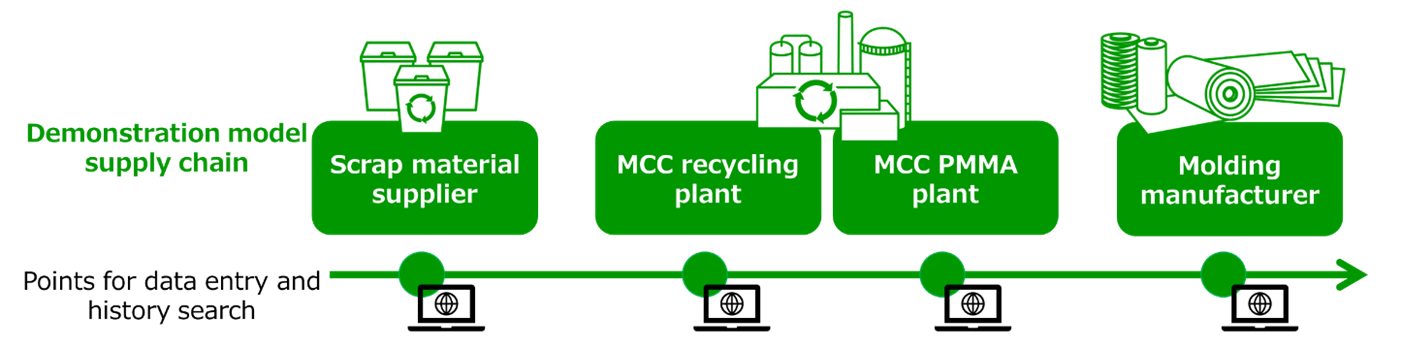

As one of its key themes, the project is working to establish a recycling system that can ensure a stable supply of high-quality recycled plastic materials for automotive parts in response to the proposed End-of-Life Vehicle (ELV) regulations, both from the perspective of establishing various evaluation technologies and building digital infrastructure for utilizing the information obtained from these evaluations. Going forward, the project also aims to create a synergistic effect by expanding the know-how gained from these efforts to other areas, such as home appliances. In this latest development, MCC conducted a demonstration test of a traceability system using blockchain to build a transparent and reliable supply chain for the acrylic resin chemical recycling supply chain that we are aiming to commercialize.

For this demonstration test, we worked with Chaintope Inc. to build a traceability system based on the Tapyrus blockchain developed by the company. We have verified that by using blockchain technology, it is possible to manage different types of waste plastics to be recycled as raw materials, such as those derived from post-industrial*1, post-consumer*1, and post-consumer and automotive uses, in a non-tamperable way, and with better transparency and reliability even in supply chains that use the mass balance method*2 in their chemical recycling.

In recent years, there has been an increasing need for traceability and digital product passports (DPP), which require visualization, proof, and sharing of the environmental friendliness of products and materials, such as the provenance of recycled raw materials and the history of quality confirmation. In our most recent tests, we have verified that by using blockchain technology, information can be properly managed and shared within a supply chain spanning multiple companies, including at chemical recycling companies. This is an important achievement in advancing the commercialization of chemical recycling operations which can produce recycled products with quality comparable to conventional products.

The Mitsubishi Chemical Group is committed to continue promoting initiatives aimed at resolving issues in our society, such as chemical recycling and traceability, and to accelerate initiatives for green transformation (GX).

*1 Post-industrial and post-consumer are recycling classifications based on the origins of waste plastic. Post-industrial materials refer to materials that are recycled before they are used by consumers, such as scraps generated in factories. Post-consumer materials refer to materials that are recycled after they have been used by consumers.

*2 Where products are manufactured by mixing multiple raw materials (e.g. petroleum-derived raw materials and recycled raw materials derived from waste plastic), mass balancing is a method of distribution management where the proportions of specific raw materials used (e.g. recycled raw materials) are allocated to arbitrary products.

[Reference]

- Press release on October 26, 2023

- Press release on February 20, 2023

- The 3rd period of the Cross-ministerial Strategic Innovation Promotion Program (SIP)

-

About Chaintope Inc.

Chaintope Inc. website: https://www.chaintope.com/en/