Process Safety and Disaster Prevention, Occupational Safety and Health

Mitsubishi Chemical Corporation

Basic Policy

Mitsubishi Chemical (MCC) creates action plans comprising annual targets, annual policies and key measures reflecting the status of activities and results of the previous fiscal year and uses said plans to carry out process safety and disaster prevention and occupational safety and health activities.

Preventing Process Safety Incidents and Occupational Injuries, Key Measures

- ■ Thoroughness and Continuation of Safety Activities

- In addition to efforts to thoroughly ensure the Basic Safety Behaviors and operations, we work to ensure adherence to safe procedures and necessary safety equipment use in construction and other operations, management of changes, risk assessment, and effective utilization of information to prevent the recurrence of incidents and occupational injuries as well as the occurrence of similar incidents and accidents.

To minimize and contain harm in the event of an accident or natural disaster, such as an earthquake, we have in place systems for rapid response within our plants and preventing the spread of damage to surrounding areas, and conduct disaster drills and other preparation accordingly. - ■ Thoroughness and Continuation of Facility Management

- To prevent incidents and occupational injuries, we properly inspect facilities for age-related deterioration and repair and replace them as needed while steadily performing regular monitoring to ensure that signs of irregularities in facilities are quickly detected and dealt with appropriately.

- ■ Human Resources Training

- We strive to train people who prioritize safety at all times and who can think for themselves, have good judgment and take action. Furthermore, to enhance risk assessments, we are proactively developing human resources with specialized risk assessment knowledge and skills.

- ■ Enhancing Safety Culture

- We are implementing initiatives aimed at realizing an interdependent* organization, in which employees remind each other to practice safe behaviors, such as the MCG Group Basic Safety Behaviors. To comprehensively understand the safety culture and particular characteristics of specific workplaces, we also conduct safety culture surveys of all employees at specific workplaces every three years and analyze the results with the help of third-party experts to improve on the weaknesses of the surveyed workplaces.

- *The Bradley Curve™'s four stages of cultural maturity as it relates to safety:

Reactive: People don't take responsibility and believe incidents will happen.

Dependent: People view safety as following the rules. In a Dependent culture, incident rates decrease, then plateau.

Independent: People take responsibility and believe their actions make a difference, helping further reduce incidents.

Interdependent: Teams across the organization work together and feel ownership for safety performance. They believe zero injuries is possible when everyone contributes to that goal.

- *The Bradley Curve™'s four stages of cultural maturity as it relates to safety:

Focus: Promoting the Consistent Practice of the MCG Group Basic Safety Behaviors

MCC and its Group companies are working to raise awareness to ensure that all employees consistently practice the MCG Group Basic Safety Behaviors.

We continually work to ensure that these basic safety practices are firmly established by displaying posters, digital signage, and other such efforts.

Risk Assessment

MCC conducts robust risk assessments of processes, equipment, operation, work procedures, construction, chemicals, and other aspects in an effort to prevent process safety accidents and occupational injuries. During the risk assessment process, we identify, evaluate, and take steps to reduce risks from the perspectives of process safety, personal safety, environment, and health. We endeavor to increase the comprehensiveness by identifying risks not only during routine operations but also during non-routine situations, such as when responding to problems. Furthermore, to effectively reduce risks related to changes, we use mechanisms for identifying all changes and conduct risk assessments and otherwise manage change under the supervision of expert technicians.

Enhancing Self-Directed Process Safety

MCC’s three plants in Ibaraki, Tokai (Mie), and Okayama are accredited by the Minister of Economy, Trade and Industry as having high-level process safety under the High Pressure Gas Safety Act. These plants continually improve the level of process safety by creating mechanisms in line with the requirements for accreditation under the High Pressure Gas Safety Act, such as 1. Process safety management and inspection frameworks, 2. Continuous improvement of process safety systems via PDCA cycles, 3. Risk assessments, and 4. Education and training.

In addition, we are proactively working to advance smart process safety to address changes in the environment and social issues, including dramatic advances in technology, such as IoT, big data (BD), AI and drones and other disruptive technological innovation; increasingly serious and frequent disasters; the risk of major earthquakes; the aging of plant facilities; and decreasing numbers of process safety personnel. We are leveraging the latest in digital transformation (DX) to further improve the level of process safety management and enable people to make more refined decisions based on accumulated data.

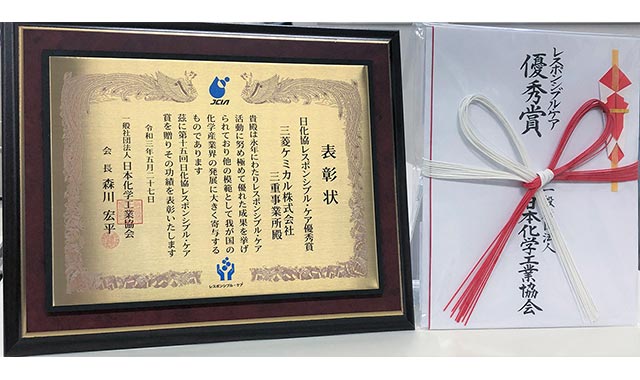

Focus: Conducting joint patrols by multiple business units and internal section patrols

MCC’s Mie Plant implements joint patrols involving facility management departments and operational management departments to address the desire of employees to learn about specialized maintenance and apply that perspective in patrols. This helps to more quickly detect signs of irregularities. In addition, to share expertise and provide reinforcement for weaknesses caused by differences in levels of experience with specific facilities, we are implementing departmental patrols in which employees make explicit and share their know-how, including key points to inspect during patrols and methods for checking places where changes have occurred. For these activities, the Mie Plant received the Outstanding Award in the Fiscal 2020 Responsible Care (RC) Awards of the Japan Chemical Industry Association (JCIA). This award is bestowed in recognition of process safety management enhancement activities (in the areas of infrastructure development, facility stabilization and human resource development) that serve as a model for other organizations.

Working Environment Management

Some employees within the MCC Group perform work that requires occupational health considerations, such as the handling of specified chemical substances and organic solvents and operations performed in hot or noisy conditions. To prevent health problems in these employees, the MCC Group manages working environments based on ongoing working environment measurement performed in accordance with relevant laws and guidelines and its own rules. In addition, MCC carries out a range of occupational health measures, such as implementing specialized health checkups, workplace inspections by industrial physicians and initiatives to reduce risks identified by chemical substance risk assessments.

Human Resource Development Initiatives

MCC implements human resource development using educational plans tailored to specific types of work and levels of seniority.

We carry out education and drills for employees who conduct operations at manufacturing sites to ensure that they can correctly carry out basic practices and operations and follow rules about prohibited behaviors. We also use creative techniques to help employees apply the knowledge gained through education at actual work sites. Furthermore, we carry out experiential education using facilities that provide simulated experiences of process safety incidents and occupational injuries to increase employees’ sensitivity to danger.

For technical staff, we also provide chemical engineering education and carry out such initiatives as mandatory participation in safety assessments of processes at their respective work sites. Through such efforts, we are developing chemical process safety engineers with specialized knowledge of chemical substances and reactions and risk assessment methods.

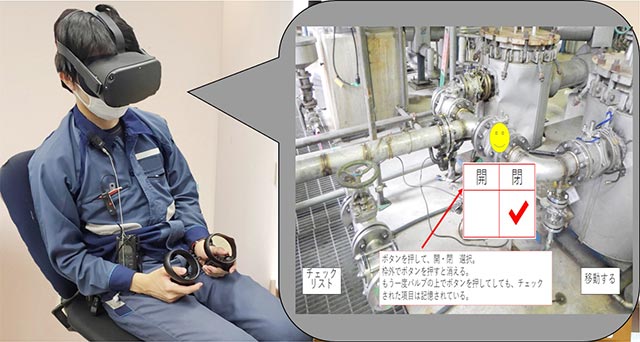

Focus: Training Using VR Technology

MCC’s manufacturing sites are introducing a training and drill system that utilizes virtual reality (VR). This system allows employees to virtually experience accidents, such as falls and being caught or entangled in equipment, to heighten their sensitivity to danger and help prevent occupational injuries. The system can be used to practice on-site work (such as opening and shutting valves) as well as to drill employees in basic operations, such as the handling of tools and correct work posture and position. We expect it to be very useful for developing plant operators.

MCC’s Okayama Plant operates a VR danger simulation training system. We have introduced the VR system to recreate dangerous circumstances and provide simulated experiences that are difficult to achieve using conventional practical safety training equipment.

By having employees experience simulations with the system, we are striving to further enhance their sensitivity to danger.

At MCC’s Mie Plant, to enhance employee training, we have created and operate a VR training program for implementing an emergency response to a stop the plant’s raw material feed. The program uses video from the actual site and helps employees learn how to implement emergency measures, such as opening and closing valves. Employees who have undergone the training have responded positively, noting that it allows them to train by themselves whenever they have time, clearly indicates which actions are correct and incorrect, making it easier to learn, and allows them to undergo training appropriate to their knowledge level. We thus expect that the system will help save time and accelerate employee training.

Accident and Natural Disaster Response

MCC has in place a range of countermeasures to minimize and contain harm due to accidents and natural disasters. We evaluate potential external effects, including impact on surrounding areas, and establish response procedures to be implemented in the event of a disaster. We also conduct training based on scenarios in which accidents occur simultaneously at multiple facilities or plants due to large-scale natural disasters or other factors. Through such efforts, we maintain an emergency response system.

Earthquake-Resistant High-Pressure Gas Equipment

MCC uses earthquake resistance design standards to evaluate the earthquake resistance of such facilities as spherical storage tanks with welded steel pipe braces and high-pressure gas facilities designated as vital in terms of earthquake-resistant design. Based on such evaluation, MCC draws up plans to improve facilities where necessary and advances earthquake countermeasures in line with said plans.

- Spherical storage tanks with welded steel pipe braces

We completed earthquake countermeasures for the nine tanks found to require them. - High-pressure gas facilities designated as vital in terms of earthquake-resistant design

We completed earthquake countermeasures for the 28 tanks found to require them.