Logistics

Mitsubishi Chemical Corporation

Basic Policy

Mitsubishi Chemical (MCC) strives to put safety first and promote strict compliance, risk management, respect for human rights and communication with business partners in order to realize KAITEKI. Based on a product stewardship approach, we are promoting KAITEKI logistics to earn the trust of customers and society in logistics operations.

Hazardous Materials Transport Initiatives and System to Prevent External Harm in Case of an Accident

MCC focuses considerable effort on ensuring the safe transport of hazardous materials.

Related MCC departments and logistics subsidiaries collaborate closely through meetings on responsible care and risk management, and implement measures aimed at reducing problems, accidents, and occupational injuries.

In addition to initiatives aimed at preventing accidents, we also conduct regular disaster drills with logistics subsidiaries and are taking steps to address the risk of a serious road accident through a contract and drills with the Maritime Disaster Prevention Center. For products that present particularly high risk if stolen or lost, we have established our own management standards that we use in the transportation and storage of such products. We work with logistics subsidiaries to ensure that all shipments are accompanied by yellow cards*1 and educate our business partners about the chemical properties of our products and safety. In these ways, we work to enhance understanding of the products being transported and sensitivity to safety.

- *1Yellow card: A document that contains emergency safety procedures to be taken in the event of a transportation accident and contact information for MCC.

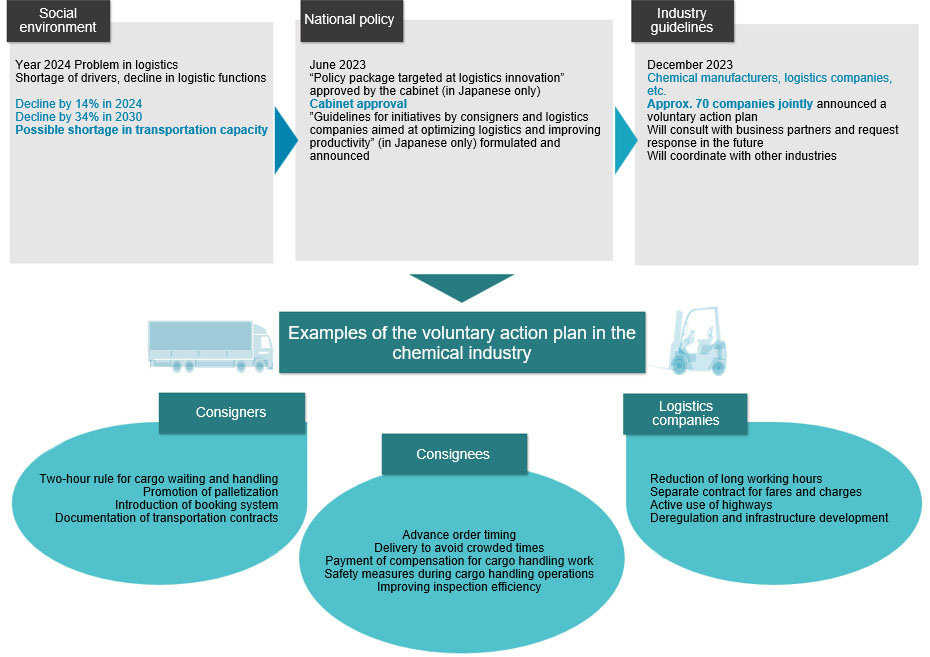

Participation in the Chemicals Working Group as Part of the Solution to Logistics Problems

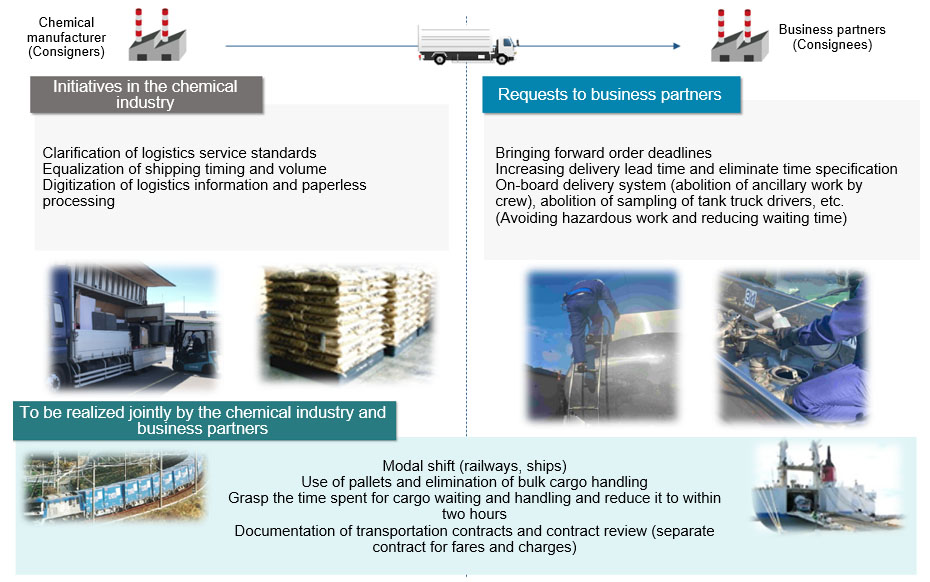

MCC is participating as one of the companies serving as the Secretariat for the Chemicals Working Group*3, established in the Physical Internet*2 Realization Council led by the Ministry of Economy, Trade and Industry and the Ministry of Land, Infrastructure, Transport and Tourism. The Chemicals Working Group announced joint voluntary action plans*4 for logistics involving chemical manufacturers and logistics companies in December 2023 to address the 2024 problem in logistics. They are pursuing reduction in the workload of drivers and stabilization of the supply chain. The working group has also formulated action plans for reforming commercial practices in logistics, standardization, pursuit of digital transformation (DX) and is educating stakeholders and implementing these and other measures with the aim of realizing sustainable logistics that achieves both productivity and safety and reduction in CO2 emissions in the medium to long term.

- *2Physical Internet: A concept that aims to improve logistics efficiency by standardizing various interfaces and sharing information on logistics resources across different companies and industries to optimize storage and transportation routes.

- *3Chemical Working Group: Established in July 2023 (Working group chair: Yuji Yano, Professor, Ryutsu Keizai University/Secretariat: Mitsubishi Chemical Group, Mitsui Chemicals, Inc., Tosoh Corporation, and Toray Industries, Inc.). There are 80 participating organizations, mainly consisting of cargo owners and logistics companies (79 companies and one university as of May 2024). Relevant divisions of the Japan Chemical Industry Association, Japan Petrochemical Industry Association, Ministry of Economy, Trade and Industry (METI) and Ministry of Land, Infrastructure, Transport and Tourism (MLIT) also participate.

- *4Voluntary action plans for chemicals to streamline logistics and improve productivity(in Japanese only)

Pursuing Joint Logistics with Other Companies in the Same Industry

The shortfall in capacity for logistics transport and storage is a serious problem in the chemical industry and the 2024 problem in logistics is emblematic of this.

Trial calculations indicate a shortfall in commercial truck transport capacity of 34% in 2030 if nothing is done to address the problem.

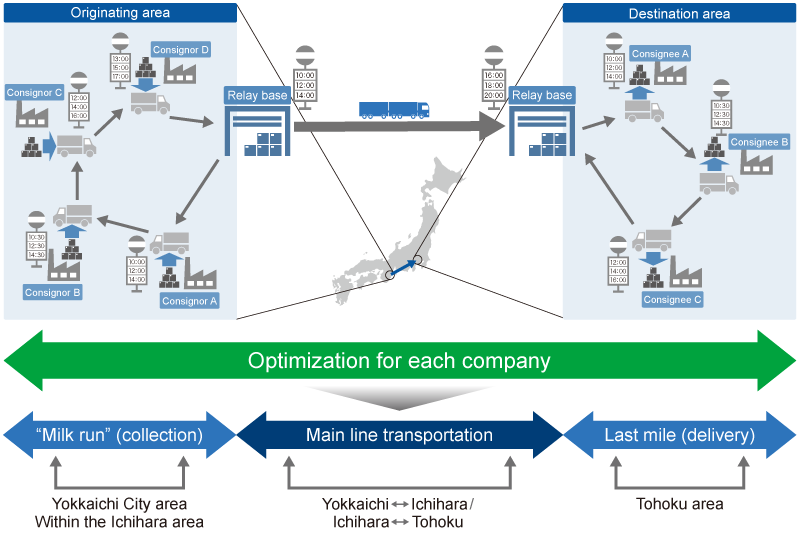

Chemical logistics has a wide range of transportation methods and conditions, owing to the special characteristics of the physical properties, form of packaging, weight, and other characteristics of cargo. Because companies can be both originating and destination cargo owners in their relationships with each other, there are limits to what one company can do to solve the 2024 problem and other problems in logistics. MCC is therefore striving to standardize and optimize logistics and is pursuing joint logistics across companies.

The Chemicals Working Group launched a demonstration test aimed at realizing joint logistics in October 2024. They aim to build a transportation model that can be expanded nationwide in Japan in the future and are using digital technology to build a platform for joint logistics to optimize transportation, based on the transportation data of the four companies serving as the Secretariat.