Mitsubishi Chemical Corporation develops technology to coat paper packaging material with gas barrier resin SoarnoL solution—Oil resistance makes SoarnoL aviable PFAS substitute—

December 23, 2025

Mitsubishi Chemical Corporation (Head Office: Chiyoda-ku, Tokyo; President: Manabu Chikumoto; hereinafter “MCC”) hereby announces the development of a technology that coats paper substrates with a solution of the SoarnoL™ resin used in food packaging materials to impart gas barrier properties and oil resistance.

SoarnoL™ is an ethylene vinyl alcohol copolymer (EVOH) developed using proprietary MCC technology that offers high gas barrier performance, oil resistance, and transparency. Used as films, sheets and other food packaging materials by being combined with other resins and thermoformed, SoarnoL™ helps preserve food flavor and quality longer, thereby contributing to reduce food loss.

The technology developed by MCC enables the formation of a stable barrier layer by simultaneously coating paper substrates with SoarnoL™ solution and an anchor coating agent. This technology imparts SoarnoL™’s excellent gas barrier properties and oil resistance to the paper

While PFAS* are commonly used to enhance the oil resistance of paper packaging materials, this new technology achieves oil resistance surpassing that of PFAS-based packaging materials even under high temperatures and foldling. SoarnoL™ meets the high hygiene standards required for direct food contact, making it suitable for food packaging applications such as fried chicken and hamburgers. With PFAS regulations tightening globally, demand for PFAS-free oil-resistant paper is expected to grow, so MCC will be seeking assessments from customers and others as it aims for adoption sometime in fiscal year 2026.

MCC plans to exhibit this technology at the New Functional Materials EXPO 2026 to be held at Tokyo Big Sight from January 28 to 30, 2026.

MCC’s “KAITEKI Vision 35” management vision identifies “food quality preservation” as a business focus area. By providing environmentally conscious materials that support food quality preservation, MCC will be contributing to societal sustainability.

* Per- and polyfluoroalkyl substances: a general term for organic fluorine compounds formed by the bonding of carbon and fluorine. While widely used for their water and oil repellency as well as heat and chemical resistance, these compounds are persistent and bioaccumulative and have long-range transport potential, prompting regulatory and risk management initiatives in numerous countries.

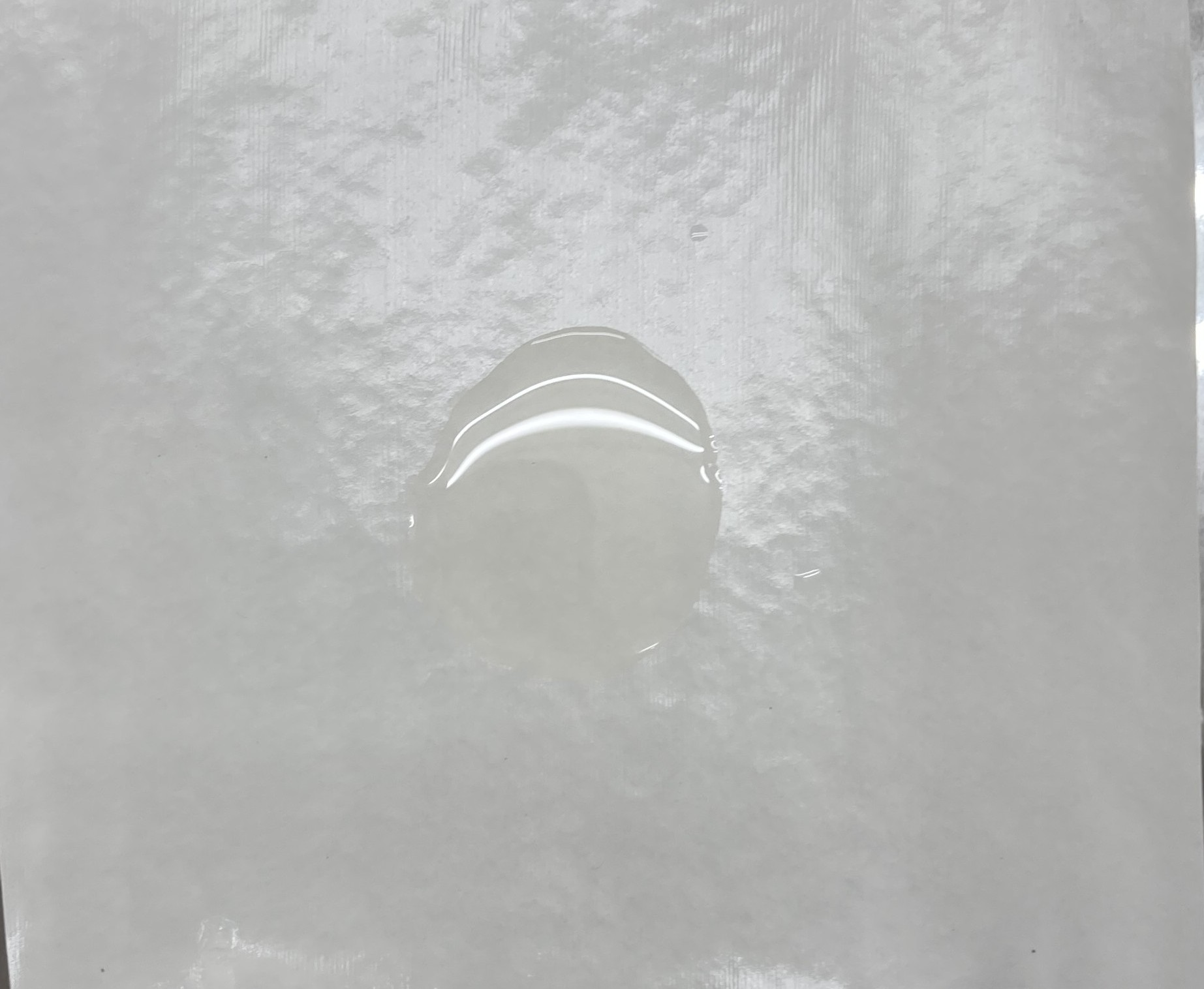

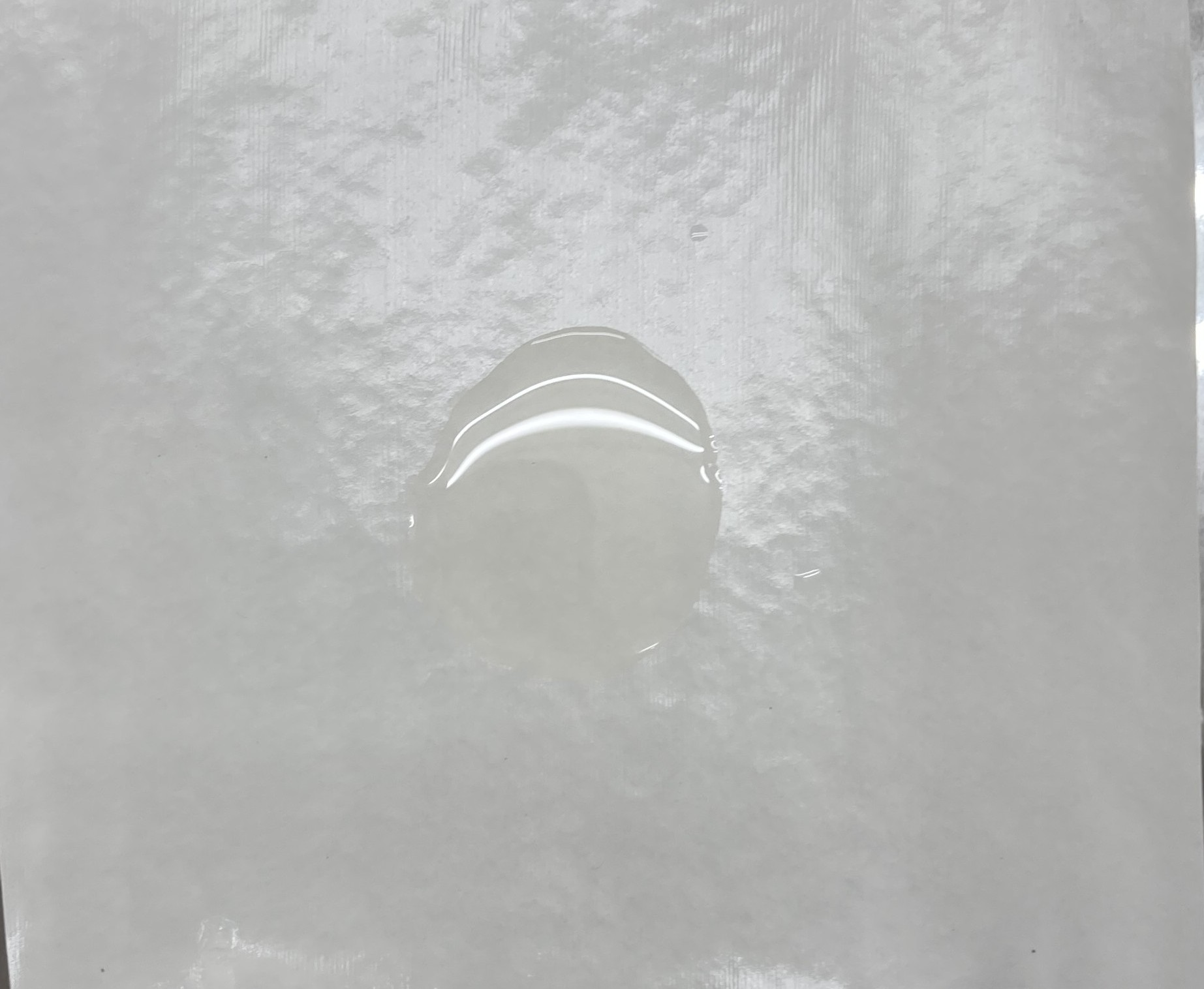

Appearance after dripping vegetable oil onto a coated surface and leaving it for 24 hours Examples of oil-resistant paper in use

Appearance after dripping vegetable oil onto a coated surface and leaving it for 24 hours Examples of oil-resistant paper in use

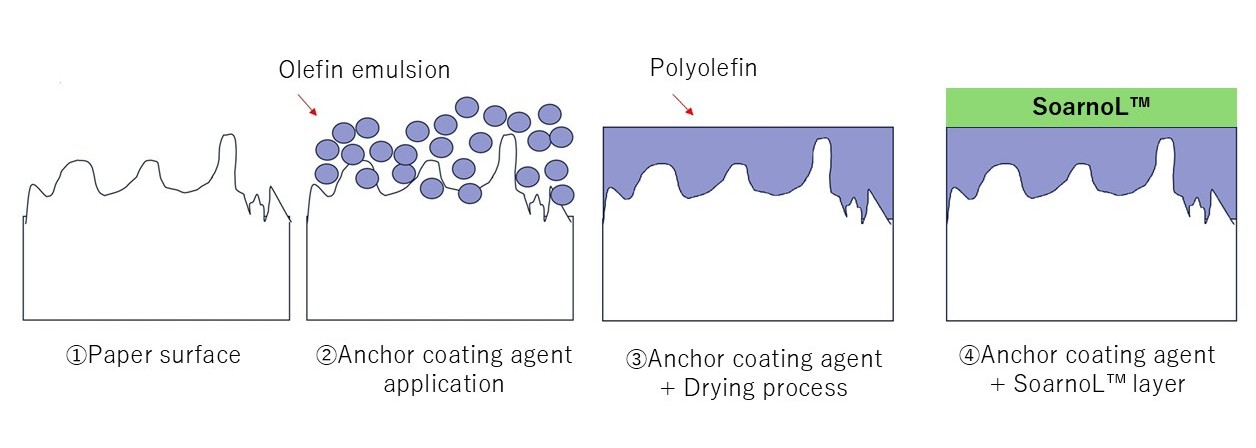

Coating a paper substrate

SoarnoL™ is an ethylene vinyl alcohol copolymer (EVOH) developed using proprietary MCC technology that offers high gas barrier performance, oil resistance, and transparency. Used as films, sheets and other food packaging materials by being combined with other resins and thermoformed, SoarnoL™ helps preserve food flavor and quality longer, thereby contributing to reduce food loss.

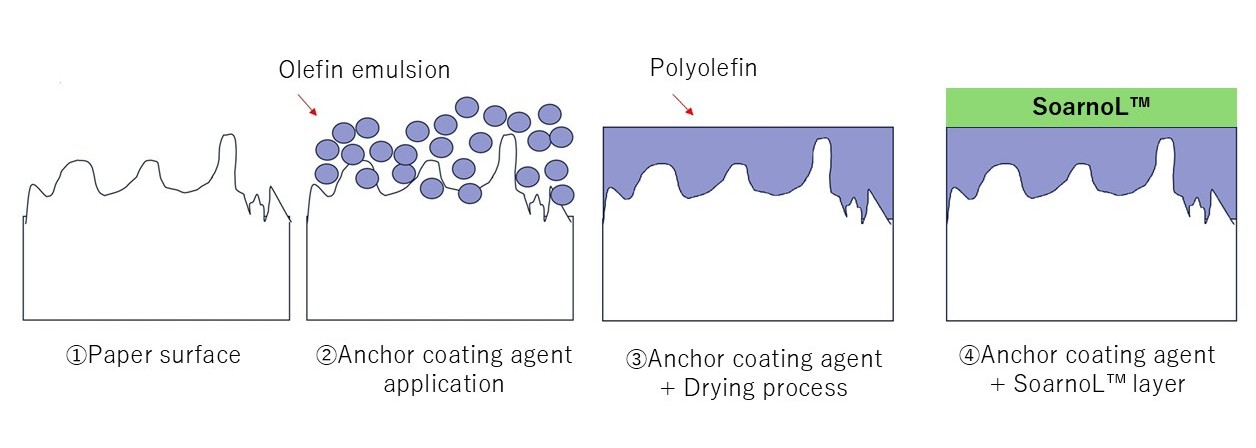

The technology developed by MCC enables the formation of a stable barrier layer by simultaneously coating paper substrates with SoarnoL™ solution and an anchor coating agent. This technology imparts SoarnoL™’s excellent gas barrier properties and oil resistance to the paper

While PFAS* are commonly used to enhance the oil resistance of paper packaging materials, this new technology achieves oil resistance surpassing that of PFAS-based packaging materials even under high temperatures and foldling. SoarnoL™ meets the high hygiene standards required for direct food contact, making it suitable for food packaging applications such as fried chicken and hamburgers. With PFAS regulations tightening globally, demand for PFAS-free oil-resistant paper is expected to grow, so MCC will be seeking assessments from customers and others as it aims for adoption sometime in fiscal year 2026.

MCC plans to exhibit this technology at the New Functional Materials EXPO 2026 to be held at Tokyo Big Sight from January 28 to 30, 2026.

MCC’s “KAITEKI Vision 35” management vision identifies “food quality preservation” as a business focus area. By providing environmentally conscious materials that support food quality preservation, MCC will be contributing to societal sustainability.

* Per- and polyfluoroalkyl substances: a general term for organic fluorine compounds formed by the bonding of carbon and fluorine. While widely used for their water and oil repellency as well as heat and chemical resistance, these compounds are persistent and bioaccumulative and have long-range transport potential, prompting regulatory and risk management initiatives in numerous countries.

Coating a paper substrate