Mitsubishi Chemical Group expands production of its Lithomax photosensitive polymers for semiconductor photoresists – New facility at Kyushu-Fukuoka Plant to produce Lithomax for ArF and EUV photoresists –

June 12, 2024

To increase the production capacity of its LithomaxTM photosensitive polymers for photoresists, Mitsubishi Chemical Group (MCG Group), has decided to build a new facility to produce LithomaxTM for ArF (argon fluoride) photoresists and LithomaxTM for EUV (extreme ultra-violet) photoresists at Mitsubishi Chemical’s Kyushu-Fukuoka Plant in Kitakyushu City, Fukuoka Prefecture, Japan.

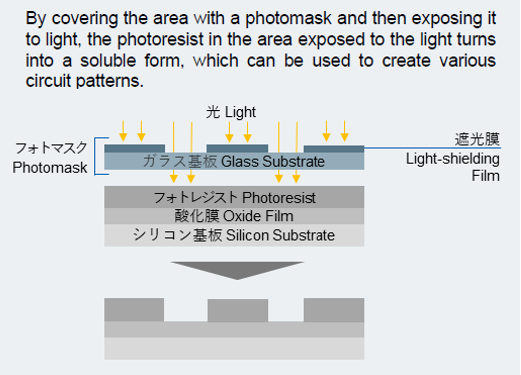

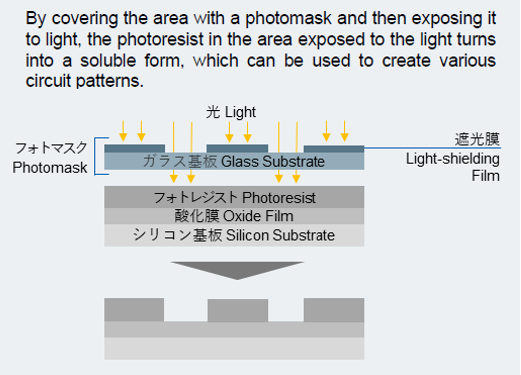

Photosensitive polymers are resins that form the main component of the photoresists used in the photolithography process to copy a semiconductor’s circuit pattern onto a wafer. With their low metal and impurity contents, MCG Group’s LithomaxTM products meet the high quality required for the miniaturization of semiconductor circuits and are used by many photoresist manufacturers. With ArF and EUV photoresists — a still growing market dominated by Japanese manufacturers — holding the key to further miniaturization, the demand for LithomaxTM as raw materials is expected to steadily grow in future.

In response to this anticipated increase in demand and to strengthen the supply chain, MCG Group has decided to establish a new production facility for LithomaxTM at its Kyushu-Fukuoka Plant to supplement the current production at the Kanto-Tsurumi Plant in Yokohama, Kanagawa. This will more than double the production capacity of LithomaxTM for ArF photoresists, and also signal the start of mass production of LithomaxTM for EUV photoresists.

With a wide range of materials and services to support semiconductor manufacturing, MCG Group will continue to contribute to the industry with a stable, high quality supply.

For more information about LithomaxTM products

https://www.m-chemical.co.jp/en/products/departments/mcc/semicon/product/1201150_8042.html

For more information about Mitsubishi Chemical Group products and services for the semiconductor industry

https://www.mcgc.com/english/news_release/pdf/01696/01962.pdf

Information is current as of the date of issue of the individual press release. Please be advised that information may be outdated after that point.

Photosensitive polymers are resins that form the main component of the photoresists used in the photolithography process to copy a semiconductor’s circuit pattern onto a wafer. With their low metal and impurity contents, MCG Group’s LithomaxTM products meet the high quality required for the miniaturization of semiconductor circuits and are used by many photoresist manufacturers. With ArF and EUV photoresists — a still growing market dominated by Japanese manufacturers — holding the key to further miniaturization, the demand for LithomaxTM as raw materials is expected to steadily grow in future.

In response to this anticipated increase in demand and to strengthen the supply chain, MCG Group has decided to establish a new production facility for LithomaxTM at its Kyushu-Fukuoka Plant to supplement the current production at the Kanto-Tsurumi Plant in Yokohama, Kanagawa. This will more than double the production capacity of LithomaxTM for ArF photoresists, and also signal the start of mass production of LithomaxTM for EUV photoresists.

With a wide range of materials and services to support semiconductor manufacturing, MCG Group will continue to contribute to the industry with a stable, high quality supply.

- Site Mitsubishi Chemical Corporation, Kyushu-Fukuoka Plant

- Product line LithomaxTM photosensitive polymers for photoresists

- Production start (planned) LithomaxTM for ArF photoresists October 2025

LithomaxTM How photoresists are used

For more information about LithomaxTM products

https://www.m-chemical.co.jp/en/products/departments/mcc/semicon/product/1201150_8042.html

For more information about Mitsubishi Chemical Group products and services for the semiconductor industry

https://www.mcgc.com/english/news_release/pdf/01696/01962.pdf

Information is current as of the date of issue of the individual press release. Please be advised that information may be outdated after that point.