New value created by “resealing”:

The evolution of packaging materials as Sales, Manufacturing and R&D work as one team

01/30/26

/ Article on Business Insider Japan

*This English text is a translation of a document originally prepared in Japanese.

*The information, positions and affiliations mentioned in this interview reflect the status at the time of the interview.

Ham and sausages are commonly used for breakfast and in lunchboxes. Many people have probably wondered, “How should I store the rest after opening the package?”

That everyday frustration is exactly what Mitsubishi Chemical’s DIAMIRON™ packaging film is designed to solve.

We spoke with three Mitsubishi Chemical members from sales, R&D and manufacturing who continue to tackle new challenges about the technologies used in this film and the vision behind its development.

“Resealing” technology that enables repeated opening and closing

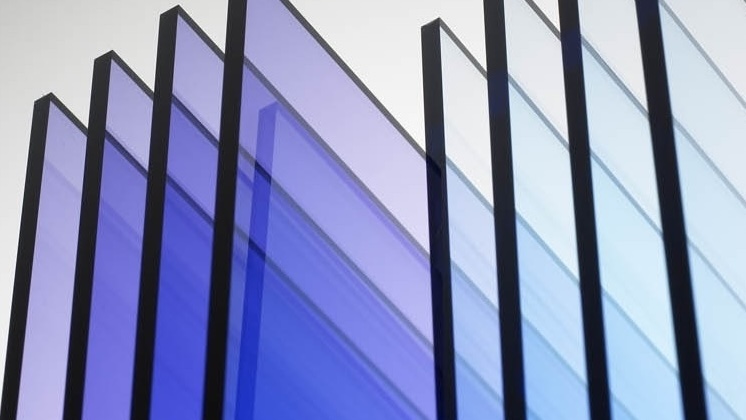

Mitsubishi Chemical’s high-performance film DIAMIRON™ is used for ham and sausage packaging. Although it appears to be a simple single-layer film, it is in fact a co-extruded multi-layer film made from several different resins.

Depending on the application and requirements, it is possible to freely combine functions such as gas barrier properties, easy-peel features, and high-temperature resistance in a single layer of film. In particular, its outstanding gas barrier properties contribute to maintaining food freshness and reducing food loss.

“The simple structure of a single-layer film is directly influenced by the properties of the resin used, making its strengths and weaknesses very apparent in the final product. On the other hand, multi-layer films such as Mitsubishi Chemical’s DIAMIRON™ layer multiple resins which enables the creation of high value-added films by leveraging the advantages of the respective materials while compensating for their disadvantages.” (Mr. Okada)

DIAMIRON™ is customized based on the needs of clients such as food manufacturers. This allows us to provide the optimal functionality for each product. One example is its resealability, which enables the package to be sealed again after opening.

“Clients consulted us saying that, once the package is opened, the contents dry out, and using plastic wrap to preserve them takes time and effort, so there was a need for something that could be repeatedly opened and resealed. That was when we started to investigate applying resealability. Recently we have been receiving an increasing number of requests for DIAMIRON™ from the perspective of its potential to reduce plastic.” (Mr. Hanari)

Three-way collaboration that led to a resolution

However, the development of a resealable film was not easy.

“The design was very challenging. In particular, we had to find ways to make the first peel smooth so as to cleanly expose only the sticky layer of the multi-layer film when opening the sealed package, while also maintaining adhesive strength from the second time onwards” (Mr. Okada).

“The resin to be used in the resealable layer was a material our manufacturing division had never handled before. When we began processing it, we faced a significant challenge: maintaining a stable extrusion during the film-casting process.

Moreover, when we changed the overall film design, we encountered various problems during storage such as the film layers sticking to each other, and the appearance becoming slightly cloudy.

There was no choice but to overcome each of these problems one at a time while having repeated discussions with our customers.” (Mr. Hirano)

Despite the challenges, we were able to bring this resealable film to market thanks to the unified efforts of our sales, R&D, and manufacturing teams.

“I believe that the driving force behind speedily developing an optimal film that met customer needs is the close information sharing between the sales, R&D and manufacturing divisions. For example, if issues and problems are discovered during the manufacturing process, the R&D team makes suggestions about what film would be best to change, and how to change the raw material formulation. Then conversely, if there is a technology that the R&D team wants to try out, the manufacturing team responds to that flexibly.

And then, sales carefully collect client requests and give us detailed feedback. I believe that all of this accelerated development allowed us to achieve the resealability that the customer requested.” (Mr. Hirano)

Changing the yoghurt lid is the first step toward reducing plastic use

With resealability added to DIAMIRON™, the small stress of feeling obliged to use the entire amount—even when you only need half—is eliminated, and the extra step of covering the product with plastic wrap to keep it from drying out is no longer necessary. The feature is also expected to contribute to reducing plastic use and food loss.

Take for example a yoghurt container of about 400 grams. Most products have a double lid system consisting of a hard plastic outer lid and a thin inner film but using a resealable film for the inner seal renders the outer lid unnecessary. This has the potential for contributing to reduction of the amount of plastic used. Moreover, with the ever-increasing number of single-person households and nuclear families, this also suits a lifestyle of using only the amount you need.

Creating the norm for 10 years from now

As applications for resealable types of DIAMIRON™ expand, the three members are looking further ahead. We asked them about future prospects.

“While sausage and ham are the main applications at the moment, we anticipate growing demand for resealable packaging in a variety of fields. Our future development will focus on addressing new challenges, such as preventing film from fogging in high-moisture products and thinning the current 60μm standard to support plastic waste reduction. We will continue to develop and make improvements.” (Mr. Okada)

“For the manufacturing division, waste reduction is a major challenge, and we will continue to engage with it. We want to further refine our manufacturing technology so we can respond quickly to proposals from the R&D side for a new raw material.” (Mr. Hirano)

“It is likely that there are no examples of using resealable film for a yoghurt lid anywhere in the world. I do believe that this is something we cannot achieve without the cooperation of food manufacturers and product end users, but I want to see a world in 10 years’ time where people can say, ‘Resealable films are the norm, right?’ This will also contribute to reduced plastic use, and I believe it is the very embodiment of Mitsubishi Chemical's KAITEKI.” (Mr. Hanari)

It may be just packaging but it still matters. Small changes can make a big impact over time. Through DIAMIRON™, Mitsubishi Chemical will challenge the social issues of reducing food loss and plastic usage, and continue to strive for the achievement of KAITEKI - the well-being of people and the planet.

Click here for the Mitsubishi Chemical's DIAMIRON™ product page.

Multilayer Co-extruded Film "DIAMIRON" | Products | Mitsubishi Chemical Corporation

Click here for the DIAMIRON™ site.

[High-Performance Packaging Film Materials with Superior Gas Barrier Properties] DIAMIRON™