PMMA Chemical Recycling

Making Advanced Materials Sustainable

02/10/25

/ TEXT BY MCG

*The information mentioned in this article reflect the status at the time of publication.

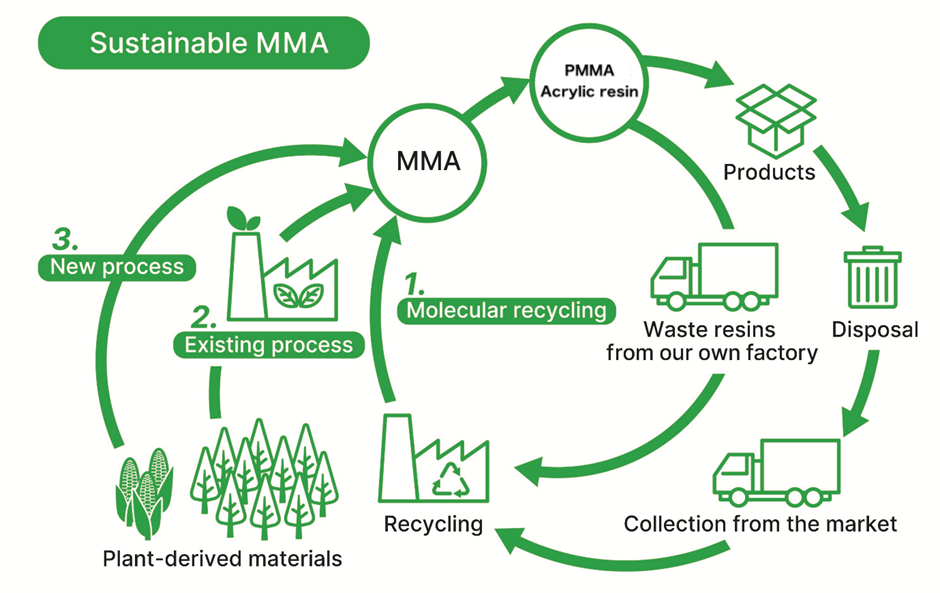

Global demand for acrylic resin PMMA reportedly exceeds 3 million tons. This plastic with excellent transparency and weather resistance has a wide range of applications, including vehicle tail lamp, signs, aquarium tanks, paints, and building materials. The Mitsubishi Chemical Group (MCG) has the world’s largest share of the market for methyl methacrylate (MMA), the raw material for PMMA. We are now working on chemical recycling to turn used acrylic resin into an MMA monomer as a raw material for manufacturing new acrylic resin.

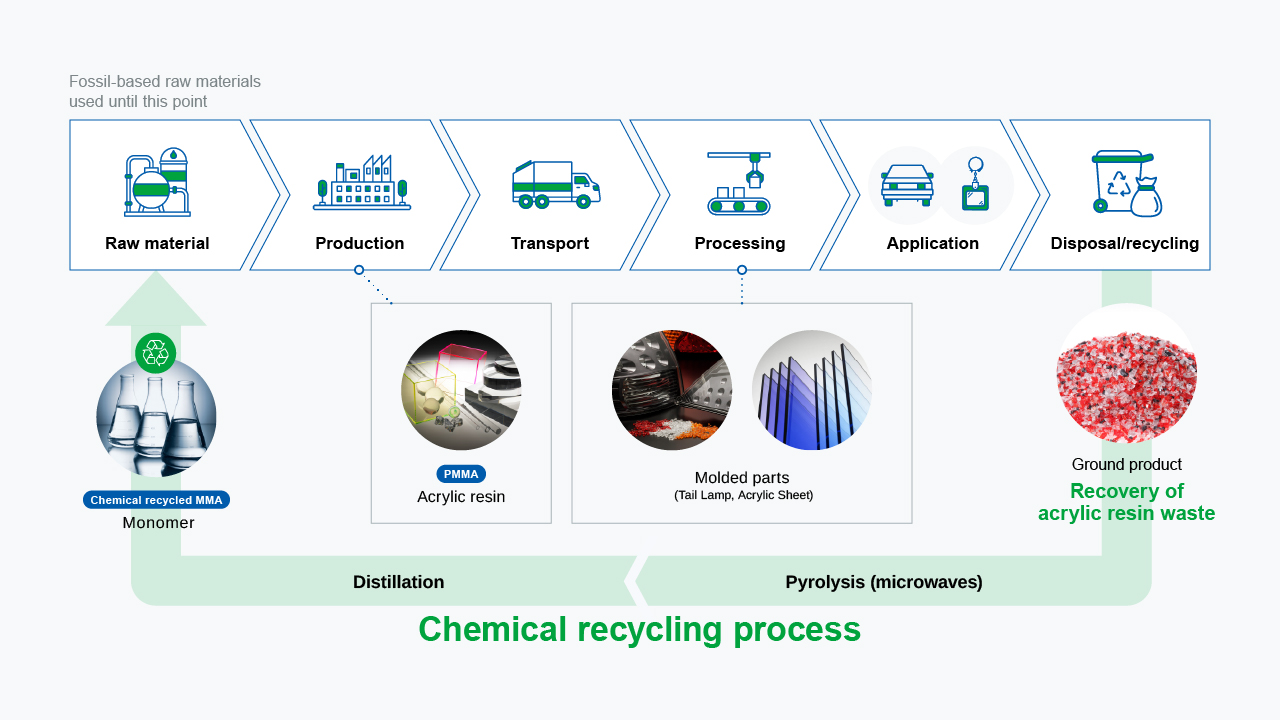

Chemical recycling with microwaves

Acrylic resin can be depolymerized with thermal decomposition and returned to its original state as MMA. This makes the resin suitable for chemical recycling. The MCG Group is working on recycling technology using microwaves. Microwaves are electromagnetic waves that have been used in household microwave ovens and in telecommunications. They can deliver heat directly to specific objects. The MCG Group has been conducting R&D with Microwave Chemical Co., Ltd. since 2021, steadily advancing the establishment of a recycling technology that employs microwaves to thermally decompose acrylic resin. Since the chemical recycling equipment runs on electricity, using renewable energy as a source of power in the future should reduce the carbon emissions during manufacturing and lower the environmental impact.

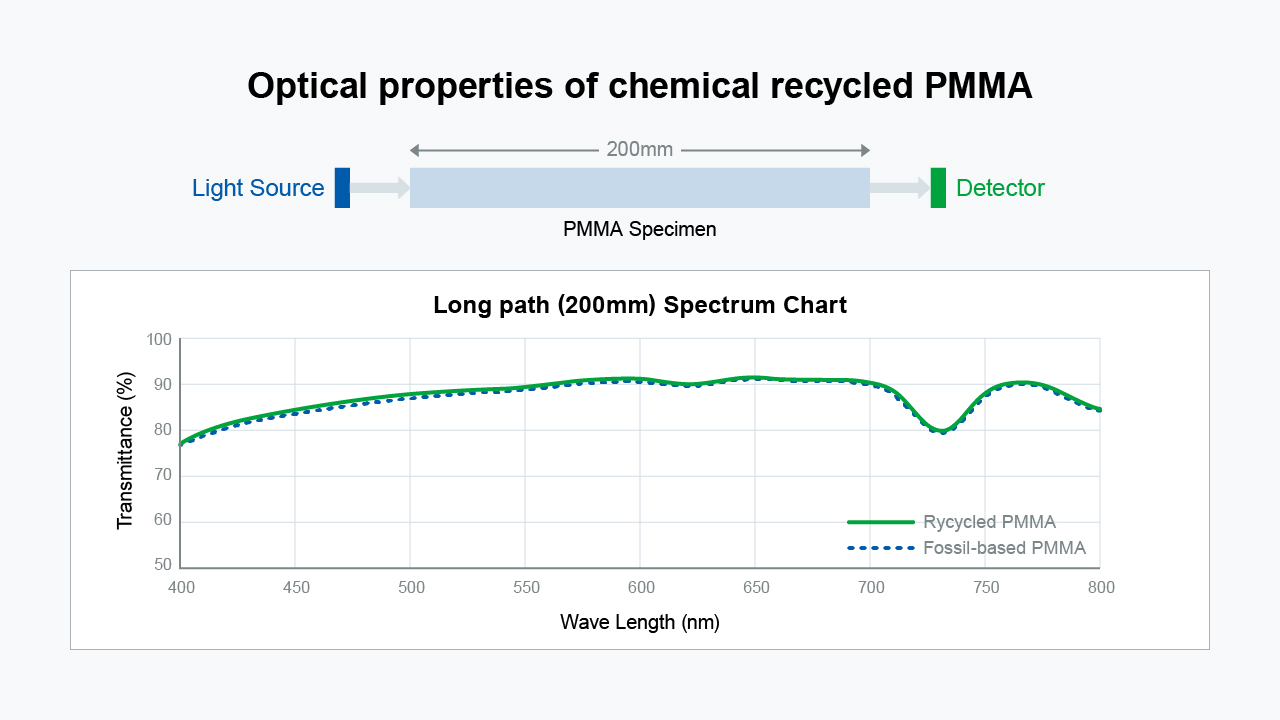

Features of PMMA chemical recycling

Once collected, acrylic resin (PMMA) can be recycled chemically regardless of its manufacturer, production method, color, molecular weight, any deterioration, or type of trace additives. The MMA monomer resulting from chemical recycling has the same quality as conventional products, while the acrylic resin made from this MMA also has the same performance and quality as a fossil fuel-based product. The recycled material is especially useful for lenses and light guides with rigorous optical performance requirements because it can be used in the same way as fossil fuel-based acrylic resin. Furthermore, the recycled material can be recycled repeatedly.

Building a circular business model

The MCG Group is building a business model for the widespread collection and recycling of used acrylic resin products. Since there is presumably a large amount of waste acrylic resin available to collect from both our manufacturing sites and elsewhere in the wider market, we are working with many companies and organizations to conduct proof-of-concept (PoC) tests and otherwise take action. For example, we are conducting a tail lamp-to-tail lamp horizontal recycling demonstration test with Honda Motor Co., Ltd., a demonstration test to recover materials from used automobiles with Tokio Marine & Nichido Fire Insurance Co., Ltd., acrylic key chain and acrylic stand collection and recycling with the Council for Acrylic Goods Recycling Project, and a demonstration test of a traceability system for chemical recycling with Chaintope Inc. Through these efforts, we aim to build a circular business model that meets the market’s needs.

Accelerating innovation, making materials green

The MCG Group is proactively developing technologies to reduce the environmental impact of PMMA. In addition to chemical recycling of waste acrylic resin, we have been working on several projects. For example, one is by developing production technology for MMA monomers that uses plant-derived materials in existing manufacturing processes. Another is a way to use fermentation to produce MMA monomer directly from plant-derived materials. Through these innovative technologies, we aim to lower the environmental impact of MMA and PMMA.