Pla-relay Project:

A New Challenge for Food Container Recycling

Through a Chemical Approach

10/10/25

/ TEXT BY MCG

*The information, positions and affiliations mentioned in this interview reflect the status at the time of the interview.

Plastic recycling is essential for creating a sustainable society. In Japan, enforcement of the 2022 “Act on Promotion of Resource Circulation for Plastics” has resulted in an acceleration of collaborative initiatives by companies, consumers and local governments.

Plastic containers are difficult to sort, collect, and recycle by material type since plastic containers that look similar may be made of different materials. The “Pla-relay Project” started in response to such issues where the local government, a recycling company, a material manufacturer, a container manufacturer, a food manufacturer and a retailer are collaborating by leveraging their respective strengths to recycle plastic containers in a closed loop using chemical recycling (also known as advanced recycling) in Kashima City, Ibaraki Prefecture. Representing the project, we spoke to Toyo Seikan Group Holdings Ltd., Kewpie Corporation and Mitsubishi Chemical Corporation about the current situation and challenges facing the food industry with regard to plastic recycling, and the new possibilities that can be created through their co-creation.

▼Related Videos

-

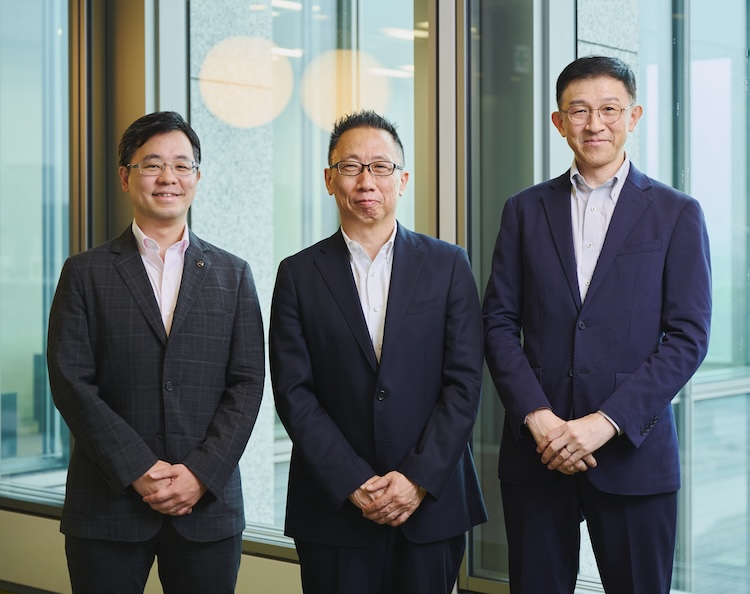

■From left:

Ippei MikiHead of the Innovation Incubation Office, Toyo Seikan Group Holdings, Ltd.

Takehiko BandoGeneral Manager, CN & CE Strategy Department, Strategy & Planning Division, Basic Materials & Polymers Business Group, Mitsubishi Chemical Corporation

Tsuyoshi HamakitaGeneral Manager of the Sustainability Promotion Department, Public Relations and Sustainability Promotion Division, Kewpie Corporation

Each player shares their initiatives for plastic container recycling

Ippei Miki, Toyo Seikan Group Holdings, Ltd. (Miki, Toyo Seikan Group):

The Toyo Seikan Group was founded in 1917, starting with can manufacturing, and expanding its business domain to glass bottles, paper cups, retort pouches and PET bottles for beverages. Packaging containers are an integral part of our daily lives, and the development and manufacturing of containers must always proceed hand-in-hand with social issues and backgrounds.

With the recent emphasis on tackling environmental issues such as climate change and effective utilization of resources, the Toyo Seikan Group regards recycling initiatives as key issues for the company’s sustainable continuity, and this led to the launch of this Pla-relay Project.

Ippei Miki: Head of the Innovation Incubation Office, Toyo Seikan Group Holdings, Ltd.

Tsuyoshi Hamakita, Kewpie Corporation (Hamakita, Kewpie):

Kewpie was the first company to produce and sell mayonnaise in Japan in 1925. In 1958, we launched mayonnaise in plastic squeeze bottles. Since then, our business has expanded to include dressings, pasta sauces, salads and prepared foods, and Aohata jams.

While our product packaging does use plastics, Kewpie is working to reduce the amount of plastic used by making containers lighter and thinner to address recent environmental issues. In addition, Kewpie is collaborating with other companies in conducting pilot programs to collect used mayonnaise and dressing bottles for closed-loop resource recycling. There are three issues to be tackled in promoting horizontal recycling. The first is removing foreign matter from the containers. The second is efficiently collecting the bottles. The third is keeping down the cost of such initiatives. Even if we can return social value to customers through recycling, it is not economically rational and not a sustainable initiative if it incurs high costs. We regard ensuring economic rationality as a long-term issue for resource recycling.

Tsuyoshi Hamakita: General Manager, Sustainability Promotion Department, Public Relations and Sustainability Promotion Division, Kewpie Corporation

Takehiko Bando, Mitsubishi Chemical Corporation (Bando, Mitsubishi Chemical):

Mitsubishi Chemical provides a wide range of products from basic chemicals to high-performance materials for mobility, semiconductors and telecommunications, medical, food and infrastructure applications. The Basic Materials & Polymers Business Group, to which I belong, is positioned upstream in the value chain and manufactures basic materials such as PE (polyethylene) and PP (polypropylene) . To make effective use of fossil resources and achieve carbon neutrality by 2050, we are also engaged in advancing recycling technologies, manufacturing bio plastics, and exploring the commercialization of chemical products derived from CO2.

In July 2025, a chemical recycling plant with an annual processing capacity of 20,000 tons, which is one of the largest in Japan, was successfully completed at the Ibaraki Plant. As we progress with the full-scale chemical recycling, we see the great value in collaborating with like-minded partners through this project to communicate the significance and potential of recycling to society.

Takehiko Bando: General Manager, CN & CE Strategy Department, Strategy & Planning Division, Basic Materials & Polymers Business Group, Mitsubishi Chemical Corporation

Chemical recycling as a Solution

Chemical recycling provides a new solution to recycled plastics that were once restricted by strict regulations or destined only for incineration or disposal. Could chemical recycling become a powerful new means to realize closed-loop resource circulation?

Bando, Mitsubishi Chemical: Chemical recycling is a technology that returns plastics to their original raw material through rapid thermal decomposition. Plastics made from this material have a quality equal to virgin (new) materials. We expect that the recycled materials will increasingly be used in fields such as food and automobiles, where their use was previously restricted due to quality, safety and hygiene concerns. Mitsubishi Chemical and ENEOS have introduced technology from the U.K. company Mura Technology to build a plant, where used plastics are decomposed and converted into oil in supercritical water. This is water under high temperature and high-pressure conditions that allows heat to be applied uniformly, enabling efficient regeneration of plastic into oil. This technology also allows different types of plastics to be recycled together. On the other hand, compared to material recycling*1, CO2 emissions are higher and the process is more complex, leaving cost-related issues. Further technology developments are needed to improve energy efficiency.

Related article:

Chemical Recycling Through Plastic-to-Oil Conversion: A new resource recycling model using advanced technology

Hamakita, Kewpie: The Kewpie group is aiming to achieve carbon neutrality and a circular economy by 2050, and its interim goal is to reduce the FY2018 level of plastic emissions by 30% by 2030. To achieve this goal, we are examining various plastic reduction and recycling methods. Kewpie packaging uses many different types of plastic materials. Given this situation, we are convinced that chemical recycling will be a powerful tool, which reduces time and effort required for sorting and enables closed-loop resource recycling.

Miki, Toyo Seikan Group: In the past when we held a workshop on sorting household waste, there was such a wide variety of types and shapes of packaging materials that even we as professionals were at a loss. We feel that there is a practical limit to separating the same types of materials from such a large volume of waste for material recycling. In that sense, we consider that chemical recycling, where plastic waste is uniformly converted into oil and can be utilized as a resource, will become an essential approach for closed-loop plastic recycling. Given these circumstances, the industry leader, Mitsubishi Chemical, has introduced new technology and established a system capable of handling 20,000 tons per annum. We are very grateful for the opportunity to work on this project together with other companies. The subject of costs came up earlier, but this has been a consistent challenge since the early stages of recycling technologies already in practical use. We believe that if recycling technologies gain understanding and acceptance in society, and industry continues its efforts to improve these technologies, cost-related issues will inevitably be resolved.

Overview of the Pla-relay Project, a collaboration of different industries

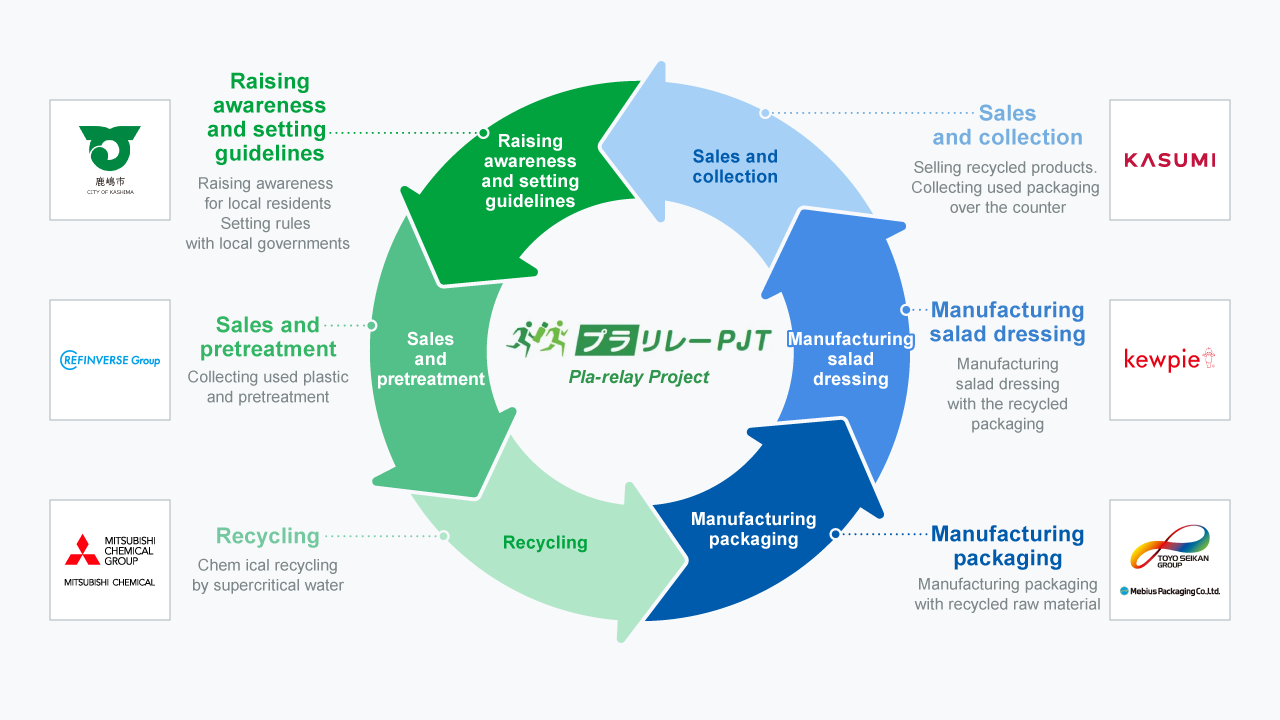

The Pla-relay Project is a comprehensive partnership agreement formed in February 2025 with the objective of closed-loop recycling of plastic containers in Ibaraki Prefecture. Each company will leverage their respective unique strengths to pass materials onto the next partner to promote the recycling of plastic through the supply chain in a relay format.

Miki, Toyo Seikan Group:

The Pla-relay Project is a plastic container recycling project that is a collaboration between the local government of Kashima City, Ibaraki Prefecture, REFINVERSE Inc, which collects, sorts and pre-treats used plastics, Kasumi Co., Ltd, which is a supermarket chain mainly based in Ibaraki Prefecture, as well as Mitsubishi Chemical, Toyo Seikan Group and Kewpie.

Specifically, the caps and inner plugs of dressing containers, including Kewpie products, are collected at public elementary and junior high schools in Kashima City and at the Kasumi Supermarket Kashima Stadium store. After pre-treatment at REFINVERSE, and recycling at Mitsubishi Chemical’s new chemical recycling plant, the Toyo Seikan Group molds the plastic resin once more into caps and inner plugs for dressing bottles. After the dressings are manufactured at Kewpie using these caps and inner plugs, they are sold at the Kasumi Kashima Stadium store and returned to residents which completes the relay-style loop.

Miki, Toyo Seikan Group: The aim of this project is not merely to bring recycled products to the market, but rather to establish a system in which plastics circulate through the entire supply chain. By completing one loop, we expect to expand its applications, such as use in other containers and products, and transferring the initiative to other regions. Various companies have already expressed interest, and our network is growing as the project progresses. We would like to see future collaboration with many companies across industries, with the aim of nationwide expansion. To lay the foundation for this, we are committed to thorough efforts, including the development of guidelines.

Bando, Mitsubishi Chemical: As Mr. Miki has said, if the Pla-relay Project expands to numerous industries and business types, and can also be adopted nationwide, it will lead to a reduction in plastic waste. For this relay, Mitsubishi Chemical is the lead runner in terms of providing virgin materials which are the main source of caps and inner plugs. At the same time, we are also the last runner in terms of recycling the collected caps and inner plugs. We recognize that this is an important role in supporting each company in the value chain to reduce waste and make effective use of resources.

Miki, Toyo Seikan Group: The Toyo Seikan Group will continue to connect the relay by molding the resin passed on from Mitsubishi Chemical into caps under stringent quality control. In addition, as a packaging container manufacturer, we believe it is our crucial role to propose the application of this solution to items other than caps as well as to communicate with a diverse range of customers and promote collaboration to expand the scope of Pla-relay to establish this as a new standard for plastic recycling.

Hamakita, Kewpie: We believe that our most important role is to continue our part in the relay and provide safe and secure dressings to all our customers. Thanks to you, Kewpie products are loved by many people. By making it widely known that Kewpie is participating in this Pla-relay Project, we hope to play a symbolic role in raising awareness and educating the public about these plastic recycling initiatives. On the other hand, it is Kasumi that does the actual store sales, so Kewpie and Kasumi will collaborate to produce advertising and promotional activities that give customers a clear understanding of these initiatives.

Miki, Toyo Seikan Group: As part of the Pla-relay Project, companies are also planning to conduct in-school classes and workshops at elementary and junior high schools in Kashima City. In the classes, we will convey the significance of plastic recycling from the perspective of packaging and food manufacturers, and in the workshops, students will be asked to sort actual plastic waste produced by their homes to experience the difficulties that this entails. Then, we will start to collect waste plastic containers around autumn and sell recycled products at Kasumi Kashima Stadium store around winter 2025. Each company is preparing to enable customers to purchase these products.

Hamakita, Kewpie: Once we have completed one full loop of this initiative, Kewpie plans to produce and publish a validation report on the closed-loop recycling of plastic packaging which will verify the project’s advantages and issues, and report on actual challenges from each company’s standpoint. We believe that this process will be necessary for our business to enhance sustainability while carefully verifying aspects such as economic rationality and stable procurement of raw materials.

Cross-industry co-creation paves the way to a recycling-oriented society

The Pla-relay Project constitutes a new step forward as a plastic packaging and container recycling initiative that is indispensable for creating a sustainable environment. We anticipate that the project will drive further acceleration in achieving a greater recycling-oriented society.

Hamakita, Kewpie: Plastic recycling initiatives are essential for ensuring the sustainability of our business. We use plastic packaging in a variety of products such as mayonnaise and dressings, and without effective recycling, we will face difficulties in supplying these products to our customers. At the same time, creating social value through recycling is equally important. We have a responsibility to recycle limited resources and not defer problems for the future. The Pla-relay Project brings together people from different industries with the same aspirations to achieve a single initiative. This project aligns with our company motto of “Enjoy Work, Share Happiness” and we will make a strong commitment to promoting it.

Bando, Mitsubishi Chemical:

Guided by the Group’s Purpose, we are committed to achieving KAITEKI—the well-being of people and the planet—by addressing social issues through the power of chemistry. As mentioned earlier, we are both the first and the last runner in this project. Our chemical recycling plant is working towards full-scale operations by the end of the 2025 fiscal year. Once this plant operates, the plastic recycling closed-loop relay will be able to continue smoothly. Looking in the future, we also aim to apply chemical recycling to other materials used by the Toyo Seikan Group and Kewpie.

But having said that, chemical recycling cannot address everything. Although it can treat a variety of resins, there are still some materials for which it is not applicable. To tackle such challenges, we would like to collaborate with Pla-relay Project members to create a movement to change the product design of food packaging materials in Japan to materials that are more easily chemically recycled. Such a movement will not be achieved by a single company. We hope that the Pla-relay Project involving multiple bodies will act as a catalyst for the further spread of chemical recycling.

Miki, Toyo Seikan Group:

In terms of container manufacturing in the past, we focused on listening to the needs of product manufacturers, but it is undeniable that we have not adequately grasped the wishes and issues of customers who actually use those containers. That is why we would like to receive requests from a variety of perspectives. Even if there are impossible demands, we believe that this is where business growth begins. Only things that customers want, and society needs will remain, and anything that doesn’t meet those needs will be eliminated. That is the way of business. We will keep that top of mind as we engage in product and service development and marketing.

If we consider that only things that customers want, and society needs will remain, then accelerating plastic recycling becomes inevitable. The Pla-relay Project isn't just about the physical act of "relaying" plastics. It also embodies the aspiration to connect and carry forward a sustainable society into the future. We want to extend this activity beyond Ibaraki Prefecture and the companies currently involved. Our wish is to expand it further so that, two or three decades from now, we can truly look back and feel that starting this project was really worthwhile, ultimately passing the baton of hope to the next generation.

- *1 Material recycling: A method of melting the same type of waste plastic to make new plastic. The advantage is lower energy consumption and CO2 emissions during recycling. On the other hand, material recycling is difficult when there is co-mingling of foreign substances or plastics made of different materials, and requires processes such as collection, sorting, and washing.

Related Videos

Watch interviews and behind-the-scenes footage and explore the key highlights of the article.

- Special Feature

-

Hear from the companies involved in the Pla-relay Project.

- Article Highlights

-

-

Key Point 1

What is the Pla-relay Project? -

Key Point 2

What are the challenges of recycling plastic containers?

-

Key Point 1