Promoting a Circular Economy

Our mission as a chemical industry company

03/24/25

/ TEXT BY MCG

*The information mentioned in this article reflect the status at the time of publication.

Today we face urgent issues such as efficient energy use, reduction of GHG emissions, and sustainable resource management to create a sustainable society. The Mitsubishi Chemical Group (MCG Group) is working to address these matters by promoting initiatives in both carbon neutrality and the circular economy.

Global trends in plastic consumption and waste

According to the latest OECD report*1, global plastic consumption is forecast to increase sharply from 460 million tons in 2019 to 1,231 million tons in 2060. Meanwhile, the global recycling rate for plastic waste is only 9%. Although there has been progress every year in the effective use of waste plastic, with the rate expected to rise to 17% by 2060, predictions still indicate that around 50% of the world’s total plastic waste will be disposed of in landfills and 20% will be incinerated. Meanwhile, the world’s total plastic waste leakage into the environment accounts for around 15%, and there are concerns that plastic waste will double to 44 million tons a year by 2060.

The chemical industry accounts for a significant proportion of industrial carbon emissions due to the substantial energy consumption of manufacturing processes. Plastics generate CO2 emissions not only during manufacturing but also disposal. Reducing these emissions is crucial to creating a sustainable society.

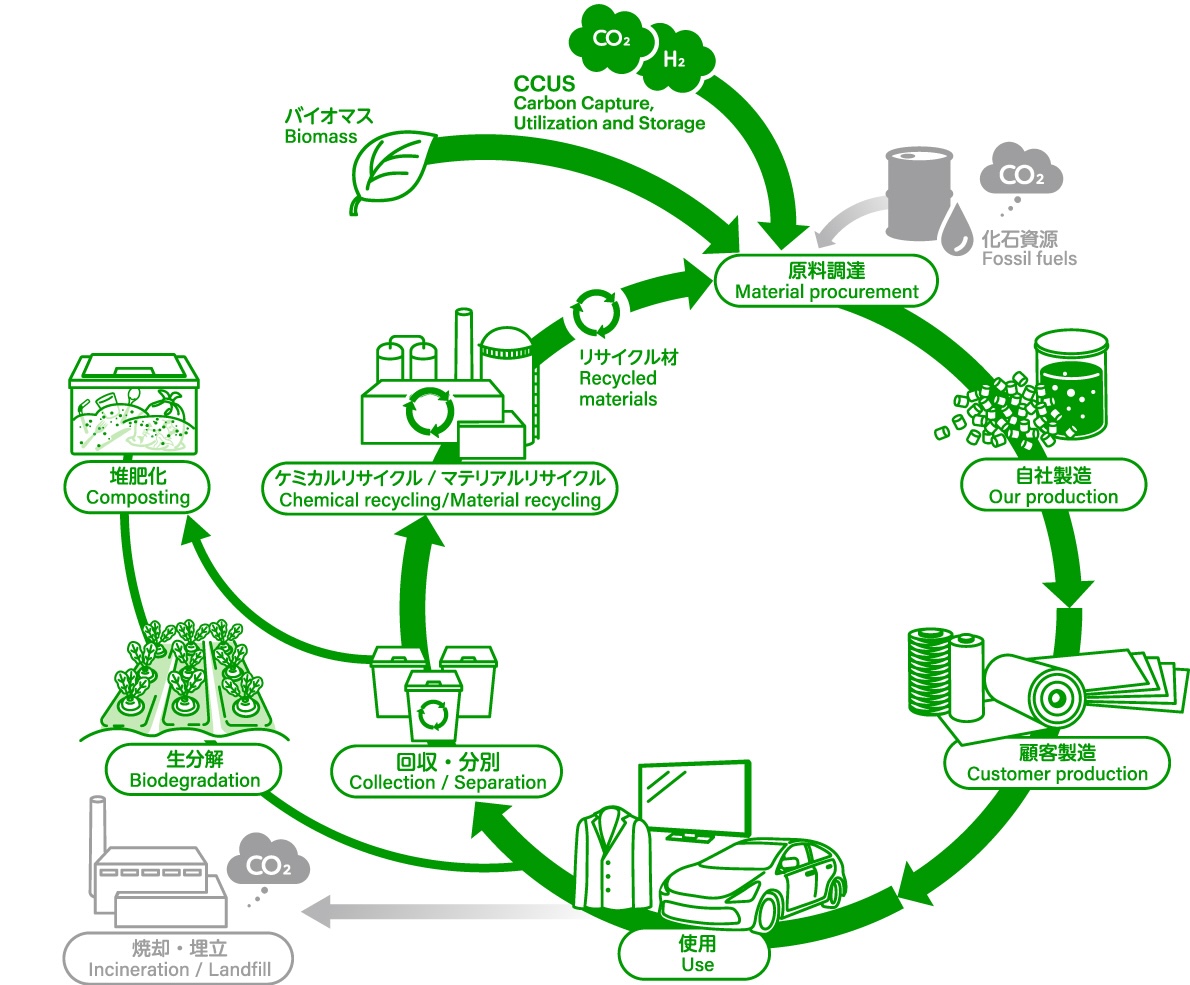

Our concept of a circular economy

As a concrete approach to a circular economy, the MCG Group is moving forward on plastic recycling, CCUS(carbon capture, utilization, and storage), as well as the production of bioplastics. For example, to recycle waste plastic back into secondary feedstock, we are working on 1) chemical recycling, which involves breaking down waste plastic through chemical processes to turn it back into chemical feedstock such as oil and monomers, and 2) mechanical recycling, which involves recycling waste plastic through physical processes such as shredding and extrusion. We are also working on a project to produce polypropylene from synthetic methanol, which is made from carbon dioxide and green hydrogen. In addition, we are pursuing the development of new materials that will contribute to the creation of a resource-recycling society. These materials include bio-based materials, as well as biodegradable materials that microorganisms ultimately break down into water and carbon dioxide. By developing these initiatives in collaboration with our partners in the value chain, from technology development to testing and commercialization, the MCG Group aims to become a green specialty company that contributes to the building of a sustainable society.

Leading the green transformation of chemical industry globally

The MCG Group is promoting the circular economy to make effective use of resources, reduce society’s overall environmental impact, and build a robust supply chain. This task cannot be achieved by a single company alone. The MCG Group aims to take the global lead in advancing sustainability in the chemical industry by leveraging its strengths as an upstream materials manufacturer and connecting diverse technologies, ideas, and supply chains, while collaborating with various industries, partner companies, local communities, and petrochemical complexes.

- *1 Source is OECD Global Plastics Outlook Database