Allowing over 99% of light to pass through, making it virtually invisible. MOSMITE™ is a new material used for art and automotive displays.

09/10/24

/ Article on Business Insider Japan

*This English text is a translation of a document originally prepared in Japanese.

*The information, positions and affiliations mentioned in this interview reflect the status at the time of the interview.

Creation of a Practically Invisible Acrylic Panel

The economist Igor Ansoff, often referred to as one of the fathers of strategic management, proposed the product-market matrix, which includes "diversification" (i.e., new markets and new products). If things go well, it can act as a catalyst for growth, but it is not an easy category to succeed in.

The Mitsubishi Chemical Group's MOSMITE™ anti-reflective film was developed from a technological seed. By applying it to both sides of an acrylic sheet, it significantly increases transmittance of light, making the sheet appear virtually transparent. Diversification into "enclaves" will allow for wide-ranging applications, from the art scene to industrial products such as mobility solutions. MOSMITE™ is in the process of advancing its social implementation, and its technology is attracting significant attention.

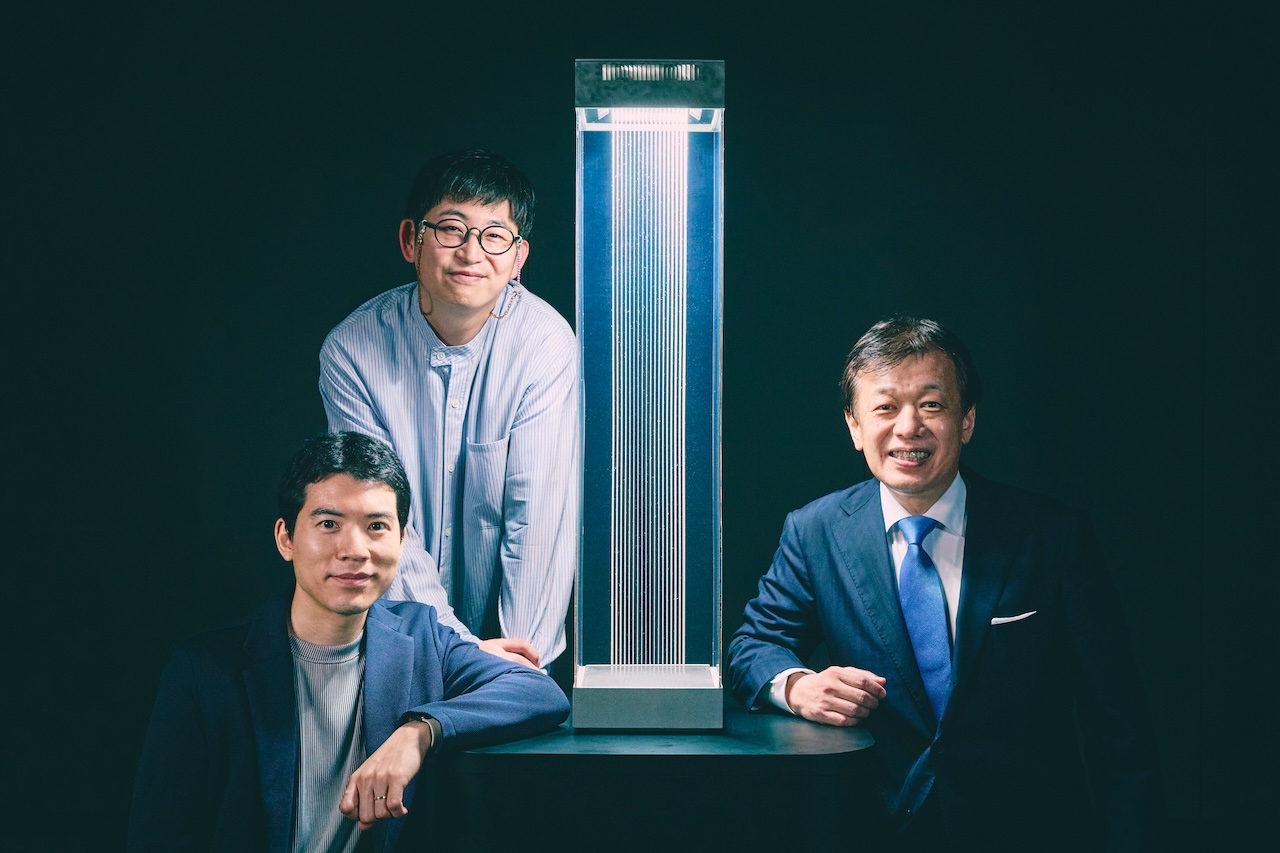

We spoke to Takashi Hibi from the MOSMITE Group, part of the Strategy & Planning Department at Mitsubishi Chemical Group's Specialty Film Division, about artistic possibilities enabled by MOSMITE™ and the product's evolution. We also interviewed Yusuke Aonuma and Kensho Miyoshi from Studio POETIC CURIOSITY, who exhibited their work "Pouring Lights" using MOSMITE™ at Salone del Mobile., one of the world's largest design fairs.

A practically invisible acrylic sheet with over 99% light transmittance

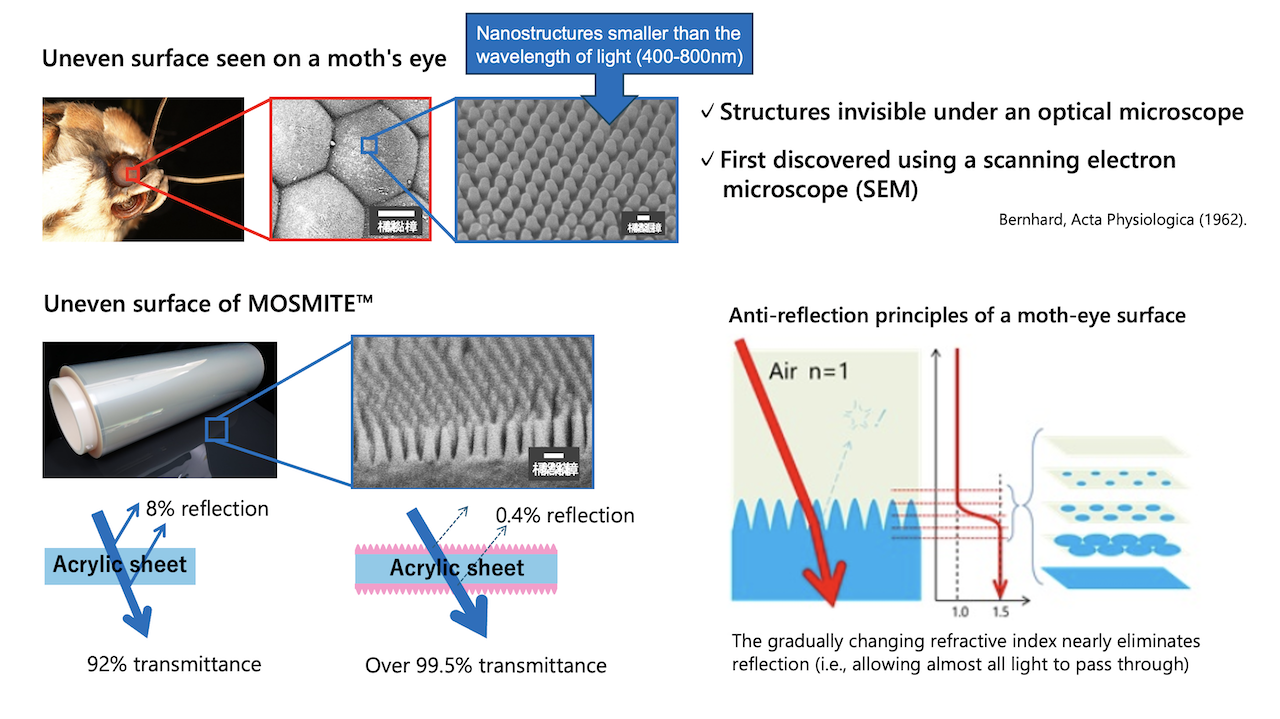

Even with only a little moonlight, a moth can fly accurately. The secret lies in the tiny bumps and hollows that cover the surface of its eyes. This uneven surface is called a moth-eye structure. When light hits the bumps, or protrusions, the refractive index changes more gradually than on a flat surface.

If there is a sudden change in the refractive index, more light is reflected. However, because the change in the refractive index of a moth-eye structure is gradual, the light's reflectance is low. The result is high transmittance. The higher the transmittance, the more light the surface can take in. This means that even weak light such as moonlight appears bright to moths.

MOSMITE™ is a biomimetic material developed by imitating this moth-eye structure. It is a film that prevents light from reflecting when it is applied to both sides of glass or an acrylic sheet. Takashi Hibi, who is in charge of development and sales for MOSMITE™ at the Mitsubishi Chemical Group, explains:

MOSMITE™ protrusions are approximately 200nm in height and 100nm in pitch. One nanometer is one-millionth of a millimeter, so there are 100 million protrusions lined up in each square millimeter. Acrylic sheets have a light transmittance of 92%, but when MOSMITE™ is applied to both sides, it increases to more than 99%, making it feel almost as if the sheet isn’t there at all." (Hibi)

The moth-eye structure was discovered in the 1960s when the electron microscope was invented, allowing scientists to observe a magnified view of a moth's eyes. Scientists learned that the ultimate anti-reflective film, which reflects no light at all, could be created by utilizing a structure of minute protrusions. However, technical challenges prevented them from achieving this.

The MCG Group began working on the creation of MOSMITE™ in the late-2000s. The R&D team discovered a technology to form microscopic nanoholes in molds using anodic oxidation.

In collaboration with an outside research institute that possessed this technology, they developed a method for forming alumina nanoholes with anodic oxidation, leading to the creation of MOSMITE™. Incidentally, anodization is a technique for creating an artificial oxide layer on an aluminum surface, commonly referred to as alumite treatment. The name MOSMITE™ comes from the words "moth" and "alumite."

"What electrolyte should we use for alumite treatment? What about voltage, concentration, temperature, and time? By controlling various conditions, we developed a technology for roll-forming regularly spaced nanoholes in large aluminum molds.

"To transfer the nanohole pattern in the mold to the film, we use state-of-the-art nanotechnology called UV nanoimprinting. It involves pouring a UV-curable resin liquid between the mold and the base film, then curing it by exposing it to UV light. MOSMITE™ is completed when we seamlessly impart the moth-eye shape to the film's surface." (Hibi)

Until now, anti-reflective films have been produced using methods such as coating and vapor deposition, but compared to those, MOSMITE™ has two distinctive features. Firstly, it can achieve low reflectivity over a wider range of wavelengths. Secondly, it offers a wide visibility angle. Because it has low reflectivity in the visible light range —where humans perceive light—and maintains that low reflectivity even when viewed from wide angles, applying MOSMITE™ to both sides of an acrylic sheet makes reflections almost completely disappear, making it look as if there is no sheet at all.

MOSMITE™ is highly compatible with immersive art

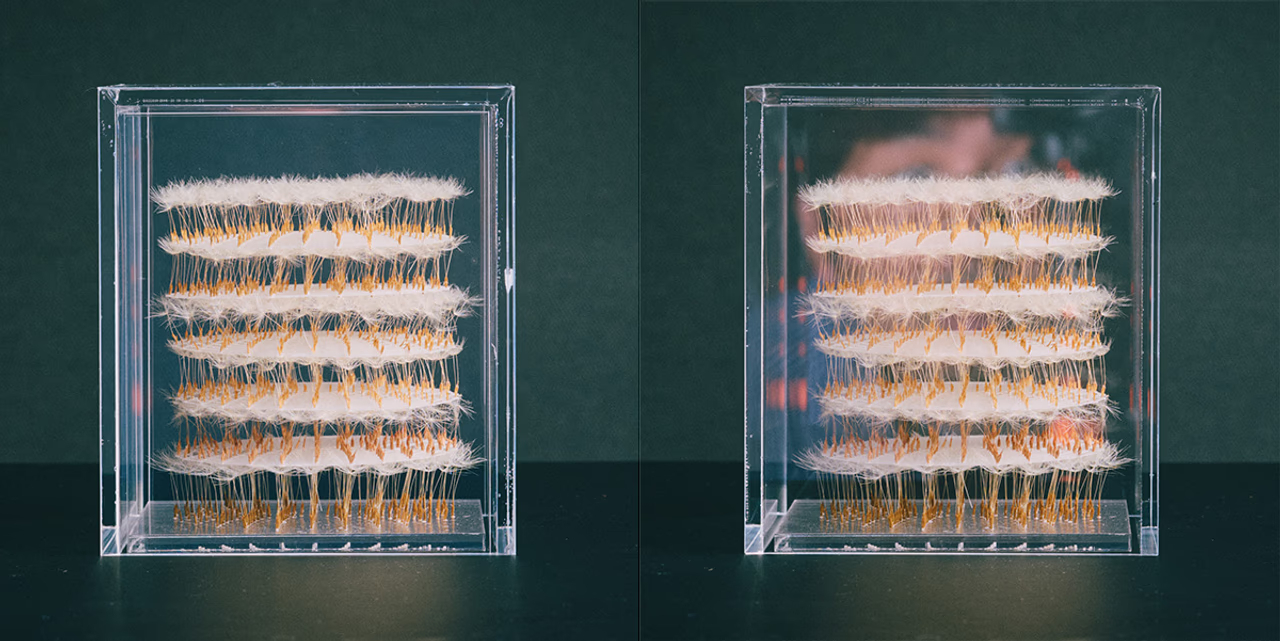

An art piece using MOSMITE™ is a floor lamp from the "Pouring Lights" series. Yusuke Aonuma of Studio POETIC CURIOSITY said, "The concept is a light installation that recreates rays of sunlight shining through the clouds." This phenomenon is known as the "angel's ladder."

"The technique we settled on involved evenly stretching 256 silk threads and illuminating them from above. At first glance, it appears as if a bundle of faint light is floating in the air. However, upon closer inspection, you can see that the light touches each individual silk thread, making them transparent and allowing you to see right through to the back. This creates a presence that feels as if it exists and yet does not.

"The challenge was that the silk threads themselves do not form a structure, so we had to surround them with acrylic or glass. However, acrylic sheets or glass reflect the faces and hands of people, which makes it impossible to immerse oneself in the faint light. Most importantly, if the supporting walls are visible, the artwork itself will look crude. To create a sense of faint light and floating, it was crucial to minimize the visibility of the walls.

"It was then that I discovered MOSMITE™. I decided to use it because I believed it could help me create lighting that makes the silk appear to float.." (Aonuma)

Dr. Miyoshi shared that he was initially skeptical when he first heard about MOSMITE™. "I thought it would just be less reflective rather than invisible," he recalled. However, he was surprised when he finally saw MOSMITE™ in person.

"With MOSMITE™ applied, the acrylic sheet looked as if it was not there, even when viewed from the front. I could touch it to confirm it was there. I can't express my surprise in words. You have to see it for yourself to really understand this. Visitors at the Milan Furniture Fair shared the same surprise.

“The structure of 'Pouring Lights' is a cuboid, but due to the design specifications, only three sides are covered with an acrylic panel featuring MOSMITE™, while the remaining side is left open. However, many visitors didn’t notice the difference between the empty side and the panels with MOSMITE™." (Miyoshi)

This is what makes MOSMITE™ particularly well-suited for art. It has already been used to frame many paintings.

"There have been incidents where individuals have thrown paint or other substances at famous artworks. This is one reason we should protect works of art with materials such as acrylic sheets. However, we must ensure that reflected light or glare does not interfere with the viewing experience. In that respect, I believe MOSMITE™ is a material that can both protect works of art and help us appreciate them." (Hibi)

Aonuma expanded on this idea, stating, "In addition to paintings, it could be utilized for sculptures and other objects."

"While some sculptures are displayed in a glass case, I still feel they obstruct the view. Works of art have a unique presence and texture. You can only truly appreciate them when you immerse yourself in them. Protecting the artwork while facilitating that immersion is key to that appreciation." (Aonuma)

Improving safety with vehicle-mounted displays and medical displays

While MOSMITE™ is highly compatible with art, it's also used with various industrial products. Currently, the most in-demand application is vehicle-mounted displays. It is applied to navigation systems and gauges in luxury cars. By increasing contrast, MOSMITE™ reportedly improves visibility and contributes to greater safety.

"It's also being adopted for medical monitors. These monitors often have covers attached, but they create reflections. The use of MOSMITE™ is increasing to prevent lesions from being overlooked due to reflections.

"Additionally, MOSMITE™ is used in electronic displays at train station platforms and on displays mounted above train doors. During the pandemic, MOSMITE™ was also applied to acrylic sheets in TV studios and other filming locations, as well as parliamentary settings to make it easier to see people's faces." (Hibi).

However, MOSMITE™ also has its drawbacks. Because of its microscopic bumps and hollows, when fingerprints get on it, oil from the skin gets trapped in the texture. It is difficult to wipe it away with a dry cloth and requires cleaning with water or alcohol. In other words, it's not suitable for surfaces frequently touched by people.

"Our initial target was large TV displays, which would provide significant scale if adopted. However, since screens are often touched, we eventually focused on areas that people don't touch or the insides of displays. This led us to find opportunities with car navigation systems and gauges." (Hibi)

The Importance of widespread adoption and profitability in innovation

MOSMITE™ features low reflection across a wide range of wavelengths, offering a wide visibility angle. These characteristics make it a promising candidate for applications such as LiDAR covers for autonomous driving. LiDAR measures the distance and shape of objects by shooting near-infrared light at them and processing the information in the reflections. Additionally, integrating MOSMITE™ into VR devices could enhance user immersion. The Group has already received requests for samples from developers globally.

From an artist's perspective, Mr. Aonuma and Dr. Miyoshi mentioned other future possibilities.

"I think it would be interesting to use it for things like department store show windows. By eliminating boundaries with MOSMITE™, the fantastic items on display will seamlessly blend with the outside world. Another good use would be for the windows of stores inside commercial facilities, allowing the vibrant interiors to seep outside and give the town more unique character." (Aonuma)

"If we apply it to an aquarium tank, it could create an unusual sight where the water and fish appear to exist in the air. Rather than just looking at the tank, visitors might experience the sensation of water itself being right in front of them." (Miyoshi)

Mr. Hibi enthused, "When I talk to artists, they suggest applications we never would have considered. If MOSMITE™ becomes even more widespread, the market may create new uses."

According to the product-market matrix proposed by economist Igor Ansoff, MOSMITE™ would fall under the category of "diversification" (i.e., new markets and new products). Mr. Hibi explained, "MOSMITE™ isn't a product that arose from a specific need. We thought about how to apply our seeds in the world, and we developed a market where we could leverage our technology." It truly represents an innovation that is moving toward practical application. In closing, Mr. Hibi shared his thoughts.

"The world is changing rapidly. New products keep coming out and we always need new materials. The materials that overturn the conventional wisdom can help transform the world and solve social issues. On the other hand, if they're going to contribute to society, it's important that they are widely implemented and they generate profits. We aim to contribute to people through MOSMITE™ by developing new applications that will come into widespread use." (Hibi)

More on MOSMITE™ here.

MOSMITE™